Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

FedEx orders placed before 4:00PM ET on Thursday, April 17th will ship same day. Freight & UPS orders have a 1:00PM ET cutoff. Orders placed after the Thursday cutoff will ship Monday, April 21st.

Note: Due to the Friday holiday, we will not be able to ship next day orders for Saturday or Monday delivery.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wiring Solutions

- Retired Products

- Programmable Logic Controllers

- Productivity1000 PLCs

- Productivity2000 PLCs

- Productivity3000 PLCs

- ProductivityCODESYS

- LS Electric XGB Series PLCs

- ProductivityOpen

- CLICK PLCs

-

Do-more H2 PLCs or

Do-more T1H Series - Do-more BRX PLCs

- C-more Touch Panels

- AC & DC Drives

- Motion Control Components

- Servos

- StrideLinx

- Pneumatics

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- AC Motors

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

Use our configuration tool to configure and order.

Do-more H2 and T1H series controllers provide the communication, programming, expansion capabilities, and logic processing needed for industrial automation projects. Form factors include a modular rack-based system (H2 series) and a space-saving stackable design perfect for field-located control.

This page will refresh momentarily.

Warning

Some of the selected facets have been selected by the {{ assistanceData.title }} Help.

Resetting/clearing ALL facets will end {{ assistanceData.title }} Help.

![Help icon]() Selection Assistance - {{ assistanceData.title }}

Selection Assistance - {{ assistanceData.title }}

Stride Interactive Product Tour Request

Do-more H2 & T1H (Micro Modular & Stackable PLCs)

Category Selection

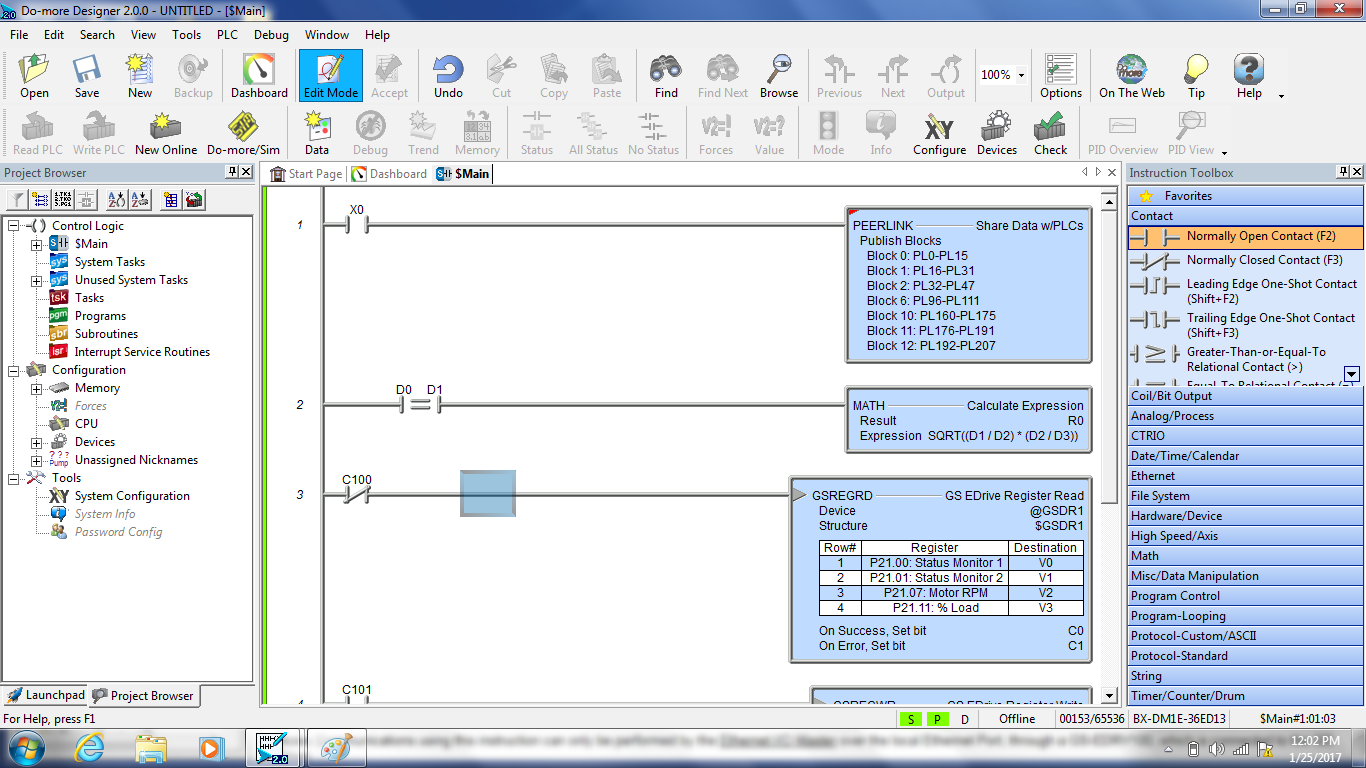

FREE user-friendly software designed to make complex operations like PID and motion control a cinch.

(click to enlarge)

The Do-more H2 and T1H PLCs combine the power of Do-more technology with two well-established I/O lines. The DirectLOGIC PLC line and the Terminator field I/O system have been serving the industrial automation industry for decades. Using the reliable I/O from these two product lines, the H2 and T1H CPUs deliver advanced control you can depend on.

- Create a brand-new controller or use the H2 CPU to modernize any established DL205 system. This CPU is lightning fast (executing a 1k Boolean program in just 0.2ms) and about 20x faster than the DL205 processors. The Do-more CPU also offers about nine times the data memory and four times the program memory of the DL205 processors.

- The T1H series PLC modules take the modular and space-saving package of our Terminator I/O line and convert it into a stand-alone control system. Using Do-more Designer as a foundation, the T1H series PLC system provides a powerful, compact control solution.

Do-more Designer is the full-featured PLC programming software for the Do-more series of programmable logic controllers. Packed with development tools and featuring dedicated high speed I/O and motion control instructions for improved functionality, a powerful spreadsheet style MATH instruction that accepts formulas and variables, and support for a mix of stage and ladder programming for a best-of-both-worlds approach that simplifies code and makes troubleshooting easier.

Another benefit Do-more Designer offers is device-centric programming. This programming method allows the user to configure software "devices" that act as liaisons between the ladder code and the hardware itself. For example, easily create a device to handle communication rates, timeouts, etc. all behind the scenes without any extra ladder programming. This feature along with the other efficiencies built into the Do-more platform, and the many tools it provides, will allow you to master any control challenge, big or small.

For part listings and specifications, go to Shop Now

CPUs

Do-more CPUs contain the processing power and I/O interface needed to perform logic operations, networking tasks, and many other functions required in an automated control system. The H2 and T1H controllers offer advanced CPUs in two distinct form factors. The rack-based H2 CPU will easily insert into the CPU slot of any DL205 base unit, and the stackable T1H CPU connects seamlessly with the compact Terminator field I/O modules. Both CPUs offer several communication options and numerous I/O expansion capabilities.

Remote I/O

The H2 and T1H PLC remote I/O modules simplify system architecture and reduce wiring costs when I/O must be located away from the local CPU. Remote I/O is ideal for segmented systems controlled by one main PLC or whenever it's more practical to mount the I/O at the machine it's controlling. Remote I/O using Ethernet is available for both PLC lines and a Modbus RTU version is offered for the T1H series.

Bases

The H2 PLC base unit provides a means of housing the power supply, CPU, and connecting all the installed I/O. These modular base units supply slots for interchangeable I/O connections to the backplane's data bus. The power supply is embedded in these base units and several power supply options and slot configurations are offered.

The stackable T1H PLC does not use a base chassis, but terminal bases are used to house the I/O modules and provide easy wiring connections. The terminal bases also provide backplane connections that will build one continuous data bus as modules are stacked together.

Power Supplies

Power supplies provide the DC power needed for proper controller operation. The Do-more T1H series PLC power supplies are available in 120/240 VAC and 12/24 VDC input versions and multiple power supplies can be installed in a single system. H2 PLC power supplies are included with the base units.

DC I/O

PLC DC I/O modules monitor ON/OFF signals or control devices that switch DC power such as limit switches and small loads such as pneumatic solenoid valves.

H2 PLCs utilize DL205 DC I/O modules and are available in input, output, and combination input/output models with up to 32 points.

T1H series CPUs work with Terminator field I/O discrete modules providing 8 or 16 points of sinking and/or sourcing inputs or outputs.

AC I/O

AC I/O modules monitor and control ON/OFF type devices that operate with AC power such as power relays, pumps, motor starters, and contactors.

H2 CPUs work with DL205 AC I/O modules and provide up to 16 points of isolated AC inputs (120 or 240 VAC) or up to 12 AC outputs (24-120 VAC or 24-240 VAC).

T1H series PLCs use Terminator AC I/O modules and provide up to 16 I/O points with a nominal input voltage of 120VAC and an output voltage range of 24-240 VAC.

Relay Output

Relay modules can be used to operate DC or AC rated devices and are available with Form C (normally open/normally closed) and/or Form A (normally open) relay contacts. T1H versions provide up to 16 relay contacts per module and H2 models provide up to 12.

Analog I/O

Analog input, output, and input/output modules to monitor and control pressure, temperature, flow, level, and other process signals. Both PLC series offer high-resolution current and voltage models with support for a wide range of analog signal levels. Sensor-specific temperature models are available to support various thermocouples and RTDs. T1H PLCs also provide thermistor support.

Communications & Networking

The H2 CPUs provide built-in Ethernet and/or serial communication ports. For systems with greater communication needs than what the CPU provides, optional networking modules are available. H2 PLC series networking modules can add up to 4 extra serial ports, an additional Ethernet port, or perform the needed serial protocol conversions.

Motion & Specialty Modules

Motion and specialty modules are designed to perform specific functions, including input simulation and high-speed counting.

The H2 series PLC high-speed I/O module can track or supply 250kHz pulse rates ideal for precision control.

The T1H series PLC high-speed I/O module is capable of tracking up to a 100kHz pulsed input and can generate up to a 25kHz pulsed output.

ZIPLink Wiring Solutions

The ZIPLink connection module and cable system eliminates the normally tedious process of wiring programmable controller I/O to terminal blocks. Available for most H2 PLC I/O modules.

Do-more PLC Accessories

Accessories for Do-more PLCs include terminal blocks, spare fuses, and replacement batteries. The powerful Do-more Designer programming software can be downloaded for free; a software USB drive is available for purchase if needed.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings