Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wire & Cable Management

- Wire & Cable Termination

- Retired Products

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Pyrometers Selector

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

Use our configuration tool to configure and order.

Programmable controllers have become the primary automation method for many industries, providing reliable, easily-modified control. In addition to discrete and process functions, controllers also perform complex tasks such as motion control, data logging, and high-level communication.

This page will refresh momentarily.

Warning

Some of the selected facets have been selected by the {{ assistanceData.title }} Help.

Resetting/clearing ALL facets will end {{ assistanceData.title }} Help.

![Help icon]() Selection Assistance - {{ assistanceData.title }}

Selection Assistance - {{ assistanceData.title }}

Stride Interactive Product Tour Request

CLICK PLUS PLCs (Stackable Micro Modular)

CLICK PLCs (Stackable Micro Brick)

Productivity1000 PLCs (Stackable Micro)

Productivity2000 PLCs (Micro-Modular)

Productivity3000 PLCs (Modular)

BRX PLCs (Stackable Micro Brick)

Do-more H2 & T1H PLCs (Micro Modular & Stackable)

LS Electric PLCs (Stackable Micro & Brick)

DirectLogic PLCs (Micro to Small, Brick & Modular)

ProductivityCODESYS

Productivity Open (Arduino-compatible)

ZIPLink Pre-Wired Connection Cables & Modules

Programmable Controllers

Programmable Logic Controllers (PLCs) contain the hardware and software used for the automation of industrial electromechanical processes, such as control of machinery on factory assembly lines, amusement rides, or food processing. They are designed for multiple arrangements of digital and analog inputs and outputs and are built for industrial environments with extended temperature ranges, immunity to electrical noise, and resistance to vibration and impact.

Four unique PLC families are available to meet industry demands and are constantly evolving to meet or exceed your needs:

- The CLICK PLC family features a compact size and easy programming, ideal for small applications and beginner projects. The CLICK PLUS series adds features such as Wi-Fi capability, motion control, data logging, and more.

- The Do-more/BRX PLC family has one of the most advanced instruction sets in the market and many other features, including REST API functionality, that allow it to stand strong against any challenge.

- The Productivity PLC family offers the utmost versatility in both hardware and software. This scalable PLC line will easily accommodate large systems with lots of I/O or smaller/segmented systems using limited I/O. With tag name programming, easy device integration that includes PS-AMC motion controllers, GS drives, and others, and WOW factors such as analog module data displays, Productivity PLCs are a perfect fit for almost any application.

- The ProductivityCODESYS PLC system utilizes the same reliable hardware as the Productivity2000 PLC series but employs a CODESYS runtime application in the processing unit. This series is ideal for those who prefer CODESYS programming but need low-cost hardware in order to implement it.

- The LS Electric PLCs are designed and manufactured by LS Electric, a well-established global PLC manufacturer with over 40 years of experience. This PLC family offers highly advanced controllers geared for motion applications, while also offering high-level features, including EtherCAT support and IEC standard programming languages, that can be beneficial in any automated system.

In recent years, open-source controllers have made headway into the industrial realm, partly due to the extremely attractive price tag. These microcontrollers are very inexpensive, small, and typically consist of a single integrated circuit containing a processor, memory, and I/O. Off-the-shelf open-source controllers were originally designed for students and hobbyists, and using one in an industrial setting is just downtime waiting to happen. For those looking to incorporate open-source control into their industrial applications, a ProductivityOpen Arduino-based industrialized controller is the solution.

Helpful Resources:

- Learn more about these awesome PLCs in the PLC Families Overview

- Need help choosing the right PLC? Check out our interactive PLC selector

- See what these controller families have to offer in our vast collection of informative videos

- Want to try before you buy? Download free controller software from our store and give it a test drive

- Check out some of our PLC product awards from industry publications

- Have questions? Our Community Forum has many automation professionals ready to help or contact our free technical support at 1-800-633-0405

- Get FREE PLC training from our training partner, InterConnecting Automation, using our PLC video training portal

- PLC Statement of Direction

For part listing and specifications, go to Shop Now

CLICK PLUS (Stackable Micro Modular PLC)

CLICK PLUS PLCs are the newest generation of the popular CLICK PLC series. Building on the original CLICK's simple design, CLICK PLUS PLCs offer the same practical control but with additional state-of-the-art features. Using the same FREE, streamlined PLC programming software, CLICK PLUS PLCs combine easy programming with enhanced security and advanced capabilities including motion control, Wi-Fi communication, and data logging.

- Six CPUs available featuring wireless and/or wired communication

- CPUs come with one or more option module slots for custom stand-alone PLC I/O configurations

- Expandable with up to 8 stackable I/O modules for 156 discrete I/O or 60 analog channels total when using two option slot modules and stackable expansion I/O

- Built-in serial and Ethernet communication options available

- The user-friendly programming software features 25 simple ladder logic and function block instructions for straightforward control of small systems

- Several specialty/intelligent option slot modules are available to add high-level IIoT features, better integration, and more

CLICK (Stackable Micro Brick PLC)

The original and very popular CLICK PLC series has been serving the industrial control industry for over 14 years and has become the micro-controller go-to choice for experienced plant engineers, electrical technicians, machine builders, as well as beginners and students.

- Starting at just $92.00 for a standalone PLC unit with built-in I/O, CLICK PLCs are the most practical brick controllers in the industry

- Over 30 standalone PLC units available with a variety of I/O and communication options built in

- PLCs are expandable with up to 8 stackable I/O modules providing for configurations of up to 142 discrete I/O or 54 analog channels

- Serial and Ethernet communication available

- The user-friendly programming software features 21 simple ladder logic and function block instructions for straightforward control of small systems

![]() Try it out - download the free software

Try it out - download the free software

Productivity1000 (Stackable Micro PLC)

Newest Additions!

- Solid state relay output, isolated thermocouple input, and higher current relay combo I/O modules

The Productivity1000 stackable micro PLC is the super compact yet highly capable member of the Productivity controller family. The P1000 is packed with many of the features of the Productivity series including tag-name programming, multiple communication ports, and easy integration, housed in a smaller, slimmer design to provide space, budget, and time savings.

- Super compact model of the scalable Productivity PLC family

- Stackable form factor with up to 752 I/O points possible

- Models with embedded I/O available

- Multiple built-in communication ports, including serial and Ethernet, supporting many industry-standard protocols and remote devices

- Programmed with the Productivity Suite software that offers tag-name programming and supreme device integration

Productivity2000 (Micro-Modular PLC)

Newest Additions!

- Solid state relay output and isolated thermocouple input modules

The Productivity2000 rack-based PLC provides advanced capabilities paired with convenience features for a very affordable price. Considering the memory, performance, versatile tag-name based software, and everything else this controller has to offer, the Productivity2000 is a great choice for any application.

- Price/performance star of the scalable Productivity PLC family

- Rack-based form factor with up to 4,320 I/O points possible

- Multiple built-in communication ports, including serial and Ethernet, supporting many industry-standard protocols and remote devices

- OLED status displays on CPU and analog modules

- Programmed with the Productivity Suite software that offers tag-name programming and supreme device integration

![]() Try it out - download the free software

Try it out - download the free software

Productivity3000 (Modular PLC)

The Productivity3000 rack-based PLC is a communications powerhouse with numerous networking options built in and a wide range of discrete, analog, and motion modules available to support various application needs.

- Rack-based form factor with over 3,000 I/O points possible

- Numerous networking options built in, including serial and Ethernet, supporting many industry-standard protocols and remote devices

- LCD status displays on CPU and analog modules

- Programmed with the Productivity Suite software that offers tag-name programming and supreme device integration

BRX (Stackable Micro Brick PLCs)

The BRX platform is the flagship controller of the Do-more PLC family. This versatile stackable micro-PLC system combines many powerful features in a compact footprint. With IIoT Integration, data logging, motion control, high speed I/O, abundant processing power, and customizable communications, BRX PLCs can easily satisfy the changing demands of industrial automation projects.

- Four micro-PLC unit form factor combinations are available (3 with built-in I/O) to provide strong system designs that fit application requirements exactly, keeping system costs to a minimum

- The BRX platform is designed to be used as a stand-alone controller or can be expanded using a wide variety of expansion modules that easily snap onto the side of any BRX micro-PLC unit

- Up to 36 built-in I/O points are provided and up to 8 expansion modules can be added for an additional 256 discrete, 128 high-speed, or 64 analog I/O points

- Ethernet and serial communication are built-in (depending on model) with a user-selected communication port providing an additional Ethernet, serial, or USB port

- Programmed using the powerful and flexible Do-more Designer software with a robust set of over 200 instructions

Do-more H2 & T1H (Micro Modular & Stackable PLCs)

The H2 and T1H CPUs round out the Do-more family of controllers and are designed to supercharge two of our time-tested hardware platforms.

- The Do-more H2 series PLC combines the proven DirectLOGIC DL205 series line of I/O modules and base units with an advanced next-generation CPU for an incredibly powerful micro modular PLC

- The T1H series PLC module takes the modular and space-saving package of our Terminator I/O line and converts it into a stand-alone control system

- Both platforms use the powerful and flexible Do-more Designer software with an extensive set of programming tools and instructions.

![]() Try it out - download the free software

Try it out - download the free software

LS Electric PLCs (Stackable Micro & Brick)

The LS Electric XGB PLC is a super-slim modular controller that offers maximum performance at minimum cost. With many motion-specific features built right in and a highly capable IEC based programming environment, these controllers deliver lots of power in a little package.

- Seven stackable, micro-PLC processors with up to 16 inputs and 16 outputs, I/O types dependent on model

- Specific inputs can be configured as (up to) 4 high-speed counter inputs and 4 preset inputs

- 2-axis or 6-axis motion control capability (using specific outputs, depending on model)

- Up to 16 ultra-precise motion control axes possible using EtherCAT expansion modules

- Ethernet, serial, and USB ports

- Supports up to 7 local expansion modules including analog I/O (up to 56 channels) , discrete I/O (up to 256 points), high-speed counter, temperature, load cell, EtherCAT, and EtherNet/IP modules

- Bus couplers allow for many more expansion I/O points and support remote I/O configurations

- The XG5000 programming software offers multiple programming languages including ladder logic and structured text

For even more motion control capabilities, the XMC motion controller builds on the XGB architecture but offers a full EtherCAT master AND several I/O points built in.

- Control 8 or 16 EtherCAT axes (depending on controller model)

- Discrete I/O and analog channels built in

- Built-in encoder inputs allow full closed-loop control

- Control up to 32 EtherCAT I/O racks with optional EtherCAT bus coupler and XGB I/O

- All programming is done within the free XG5000 software

DirectLogic (Micro to Small, Brick & Modular PLCs)

A dependable PLC platform for over 35 years, the DirectLOGIC series PLCs are fixed I/O (brick) and modular, rack-based controllers with a common programming platform. Available components are compatible with, and intended for, existing installations under the DirectLOGIC name as well as legacy private-labeled models. This series is not recommended for new installations.

ProductivityCODESYS

The ProductivityCODESYS system combines the time-tested Productivity2000 hardware with a CODESYS processor, providing a more affordable solution for those who prefer that programming environment. With the ProductivityCODESYS system, users can utilize the CODESYS IDE in many more ways, bringing a powerful world-renowned IEC-based programming language to applications large and small.

- Rack-based form factor

- Multiple built-in communication ports, including serial and Ethernet, supporting many industry-standard protocols and remote devices

- Utilizes industrial Productivity2000 analog, discrete, and PWM I/O modules

- Programmed using the CODESYS IDE and includes fieldbus, IIoT library, and visualization add-ons

ProductivityOpen (Arduino-compatible)

The ProductivityOpen platform provides all the features of a standard Arduino platform plus the added power and reliability of an industrialized controller. Designed to mimic the Arduino MKRZero microcontroller, the P1AM CPUs are is compatible with most available Arduino MKR format shields, all of the industrially-hardened ProductivityOpen shields, and can utilize numerous compatible programs found on open-source websites.

![]() ProductivityOpen Controller Overview

ProductivityOpen Controller Overview

![]() Try it out - download the free open-source Arduino Software (IDE)

Try it out - download the free open-source Arduino Software (IDE)

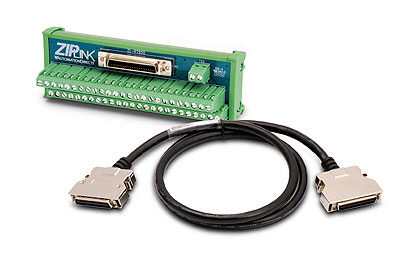

ZIPLink Pre-Wired Connection Cables and Modules

The ZIPLink prewired cable and module system eliminates the tedious process of wiring PLC I/O or other devices to terminal blocks. With a ZIPLink cable and associated connector module, I/O connections are made using half the space and a fraction of the time required to wire individual terminal block connections.

ZIPLink connector and communication modules provide screw terminals for feedthrough and fused PLC field I/O connections, high current relay output connections, communication links, and more.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...