Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wire & Cable Management

- Wire & Cable Termination

- Retired Products

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Pyrometers Selector

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

What's New in CLICK Programming Software V3.70

Support for New Modules:

1) CLICK PLUS CPUs

Slot option intelligent module preloaded with Node.js Webserver and Node-RED® for Flow based programming

2) CLICK and CLICK PLUS CPUs

Other Improvements

(See the release notes in the SW for a complete list):

- New GUI and support for restoring and backing up of intelligent modules added to Project Loader

- EDS Export to Studio 5000 Ver36 supported

What was New in CLICK Programming Software V3.60

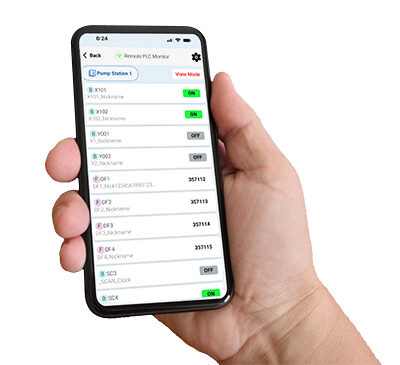

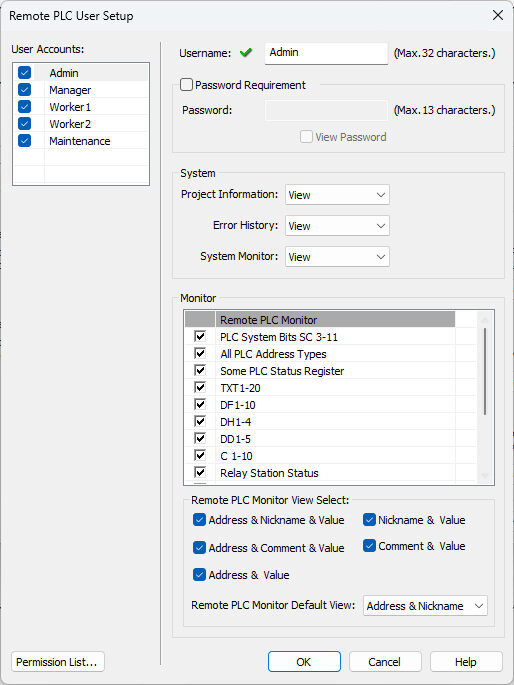

Remote PLC Mobile App (CLICK PLUS and Ethernet CLICK PLCs only)

Added support for the new Remote PLC Mobile App which allows users to view and edit PLC Registers and view PLC status from an iOS or Android mobile device.

Other Improvements

(See the release notes in the SW for a complete list):

- Users may now select to use the new Ribbon base UI or the Classic menu-based UI during the install process. Users may switch styles from the Style Menu in the top right of the UI.

- "Find and Replace" added for Nicknames. When addresses are replaced, users have the option to move associated Nicknames and comments as well

- Project Feature Settings, retain disabled settings. If a user configures a project feature, then disables it, the user configuration will be retained and enabled if the user re-enables that feature. This change makes all features consistent and affects: Software Interrupts, Ethernet/IP, MQTT, Email, and Remote PLC

What's Was New in CLICK Programming Software v3.40

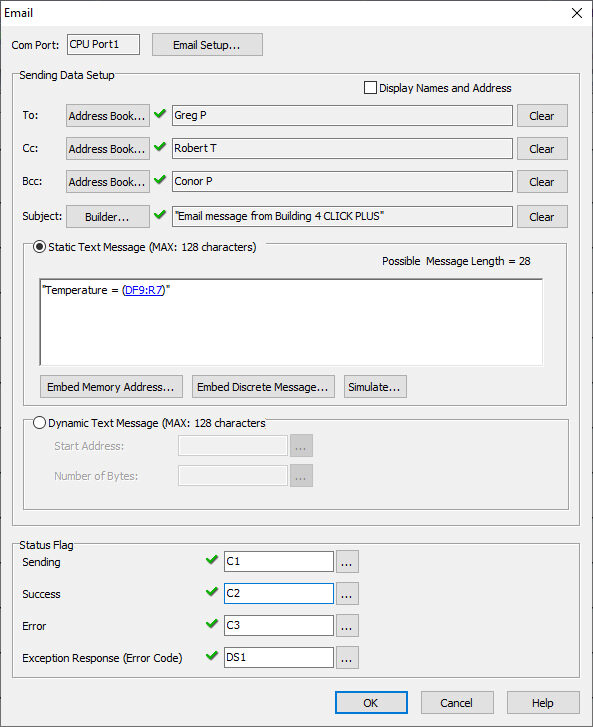

New Secure Email (CLICK PLUS only)

The Secure Email feature uses TLS encryption and is capable of sending emails with dynamic values to multiple recipients.

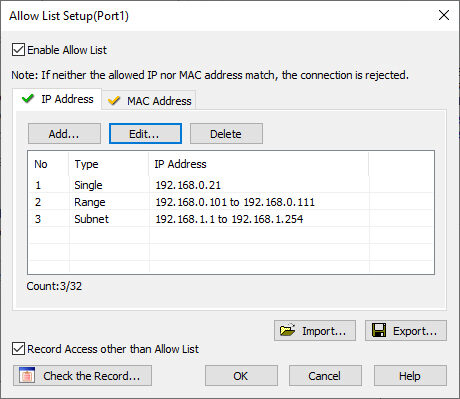

Allow List

The Allow List can be used to only allow communication with approved devices.

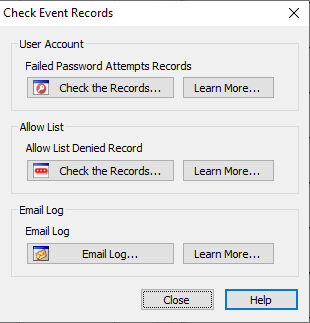

Event Record

The Event Record will log all password attempts, Allow List rejections, and email activity.

Note: CLICK Ethernet PLCs also support the Allow List and the Event Record (minus the email log).

What Was New in CLICK Programming Software v3.30

Added support for three new CLICK PLUS CPU models that have two option-slots for modules.

The CLICK PLUS option modules provide numerous I/O configurations to exactly match your application and can be changed as your needs change.

Added support for the new CLICK PLUS Data Communication Module (C2-DCM)

The C2-DCM has two RS-232/RS-485 ports and supports Modbus RTU and ASCII

Added new Embedded Discrete Message feature for Serial Port

Send ASCII Instruction that selects one of two possible text messages to output, based on the value of a discrete Memory Address

What Was New in CLICK Programming Software v3.0

Enhanced Password Security

With Version 3.0, all CLICK PLC's with Ethernet/WLAN ship from the factory with a default password. The first time a user connects to the PLC, they will be required to input the default password (click).

A new password will have to be configured in a project before it can be uploaded to the PLC.

Not required for Click C0-0*CPU Series PLC's (serial models)

Each time the CLICK programming software is connected to a PLC, the new password will be required to read or write project data to the PLC. Passwords are stored with the software project and can be edited using the programming software.

The only way to clear a password from the PLC is to reset factory defaults. This results in the project being erased from the PLC and the password defaulting back to "click".

New CLICK Software Ribbon Interface

The CLICK Programming Software now features an updated Ribbon User Interface, which can replace the Main Menu and Toolbars of the Classic interface. The Ribbon UI is intended to make navigation easier and more efficient.

Added Support for CLICK PLUS CPU's

The new CLICK PLUS CPU's introduce some impressive features to the CLICK PLC line up that will allow you to expand into more demanding applications for control.

What Was New in CLICK Programming Software v2.60

New Module Support

Added support for New CLICK High-current relay modules and Input Simulator Module

The new relay modules utilize Form A (SPST) relays for use in high-current circuits up to 10A. The input simullator module suppies 8 manually-operated toggle switch inputs for testing or simulation purposes.

What Was New in CLICK Programming Software v2.50

CLICK PID

The CLICK Ethernet PLC's now supports up to 8 PID control loops executing every 100ms. The simple PID Configuration tool saves you time

by doing most of the

work for you:

- Automatically reserves the addresses needed for the loops.

- Automatically assigns default nicknames for each PID loop tags.

- Automatically generates a DataView with PID tags

- Read and Write PID Loop configuration values to an existing PID Loop configuration of a connected CLICK PLC.

PID Loop configuration of a connected CLICK PLC.

- When Copying from a Register to TXT, added Binary option.

- The PID Monitor allows you to monitor, manually tune, or Autotune each PID loop.

What Was New in CLICK Programming Software v2.40

1. EtherNet/IP™ (Adapter Server) Protocols now supported

The CLICK Ethernet PLC models now support the EtherNet/IP as an (Adapter Server) device. This allows the CLICK PLC and its I/O to be controlled by an EtherNet/IP Scanner (Client). Take advantage of the low cost CLICK PLC I/O selection for your application needs with fast and easy configuration to your existing network.

1. EtherNet/IP™ (Adapter Server) Protocols now supported

2. Copy Instructions Improvements

The Copy Instruction offers the ability for data manipulation when communicating to other devices. Improvements have been made to this instruction that will increase the ability for users to work with data from both Modbus and EtherNet/IP devices.

Improvements include:

- Pack from Bits (C) to Registers (DS, DH, DD, DF)

- Unpack from Registers (DS, DH, DD, DF) to Bits (C)

- Pack from Words (DS, DH) to Double-Words (DD, DF)

- Unpack from Double-Words (DD, DF) to Words (DS, DH)

- When Copying from a Register to TXT, added Binary option.Â

- When Copying from TXT to a Register added ASCII Code option.

2. Copy Instructions Improvements

What Was New in CLICK Programming Software v2.30

1. Added Support for High Speed Counting and Timing on Ethernet CPU models with DC Inputs

High-speed input functions including pulse counting and frequency measurements are made simple with the user-friendly graphical user interface (GUI). Simply choose the desired high-speed function and the interface will guide you through the available features and options.

What Was New in CLICK Programming Software v2.20

1. Added Support for New CLICK Ethernet Analog CPU models

These new models support "Run time edits" and include one Ethernet port, one RS-232 serial port, and one RS-485 serial port, four discrete input and four discrete output points, up to 6 analog I/O channels, a battery back-up, and calendar/clock.

1. Added Support for New CLICK Ethernet Analog CPU models

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...

C2-01CPU-2

C2-01CPU-2 C2-02CPU-2

C2-02CPU-2 C2-03CPU-2

C2-03CPU-2 C2-DCM

C2-DCM