Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wire & Cable Management

- Wire & Cable Termination

- Retired Products

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Pyrometers Selector

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

Simple control on STEROIDS!

We've taken our most practical, most popular PLC family and supercharged it with features you wouldn't expect from a simple low-cost controller. Data logging, Wi-Fi connectability, MQTT communication and increased security measures are just a few of the impressive features offered with the CLICK PLUS PLC series. With a starting at price of only $110.00 and free easy-peasy programming software, CLICK PLUS PLCs are a "must have" for simple, affordable control with a kick!

CPU Starting at only $110.00

-

Enhanced Security

- CLICK PLUS features a set of improved security measures including:

- Encrypted password transfer and storage

- Improved port management

- Ping disable

- Session security for connected devices

- Secure email using TLS

- Allow lists

- Event records

-

FREE Mobile Apps

- The CLICK Plus provisioning mobile app for super convenient network configuration

- The Remote PLC mobile app for remote monitoring and editing of designated PLC registers

- Available at no cost to you, download on the App Store or get it on Google Play

-

Stackable I/O

- Add up to 8 additional I/O modules for applications with greater I/O needs

- Up to 156 discrete I/O points or 60 analog channels possible with stackable I/O and CPU option slot(s)

- Uses the same time-tested stackable I/O modules as the original CLICK series with analog, discrete, relay, temperature, combination and specialty modules available

Node-RED® is a registered trademark of the OpenJS Foundation

OPC UA® is a registered trademark of the OPC Foundation

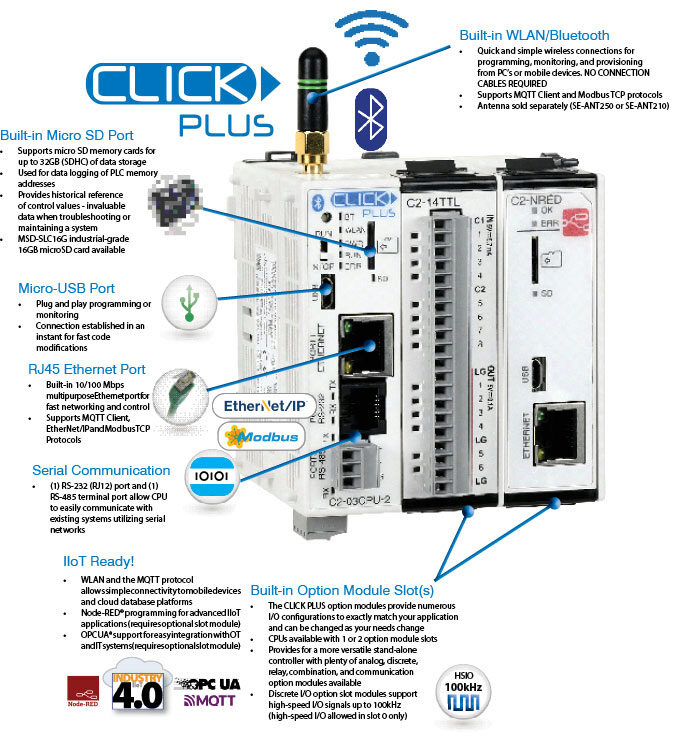

The CLICK PLUS series of controllers offers several CPU options with varying degrees of capability so you can choose the features that best fit your application. Wi-Fi connectivity, Ethernet communication, and data logging are all available options with these low-cost CPUs. You can't find features like these for under $200 anywhere else!

CLICK PLUS CPUs are also extremely versatile and can stand as complete PLC systems with custom analog and discrete I/O using the CLICK PLUS option modules, and they can be expanded with your choice of 8 stackable I/O modules for an additional 128 discrete or 48 analog I/O points.

The lowest cost model of the CLICK PLUS CPUs with great features at a great price!

C2-01CPU | C2-01CPU-2

$110.00 $154.00- WIRED ONLY CPU

- Modbus RTU, Modbus TCP, MQTT, and EtherNet/IP support

- Node-RED® and OPC UA® (option slot module required)

- Micro USB programming/monitoring port

- Ethernet 10/100Base-T (RJ45) port

- RS-232 (RJ12) serial port

- One or two option module slot(s)

- High-speed input and output support

- Enhanced security

- Free easy-to-use programming software

- Network Time Service (SNTP)

Our most affordable Wi-Fi/Bluetooth capable CPU. For those locations where wireless connections are preferred or whenever you want to cut out the time and expense needed for additional network cabling.

C2-02CPU | C2-02CPU-2

$167.00 $212.00- WIRELESS ONLY CPU (antenna sold separately)

- Modbus TCP and MQTT support

- Node-RED® and OPC UA® (option slot module required)

- Wi-Fi and Bluetooth

- Micro USB programming/monitoring port

- One or two option module slot(s)

- High-speed input and output support

- Enhanced security

- Free easy-to-use programming software

- Network Time Service (SNTP)

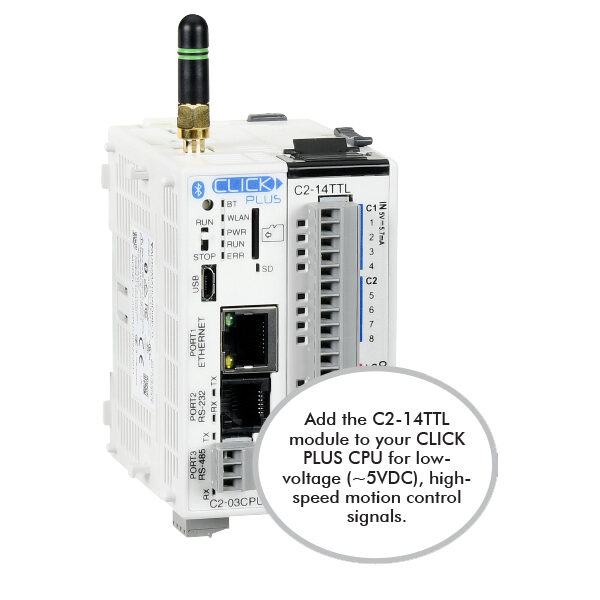

The top-of-the-line CPU, with all the impressive features of the C2-01 and C2-02 CPUs but with additional communication options and data logging support.

C2-03CPU | C2-03CPU-2

$223.00 $277.00- WIRELESS/WIRED CPU (antenna sold separately)

- Data logging (microSD support)

- Modbus RTU, Modbus TCP, MQTT, and EtherNet/IP support

- Node-RED® and OPC UA® (option slot module required)

- Ethernet 10/100Base-T (RJ45) port

- RS-232 and RS485 serial ports

- Wi-Fi and Bluetooth

- Micro USB programming/monitoring port

- One or two option module slot(s)

- High-speed input and output support

- Enhanced security

- Free easy-to-use programming software

- Network Time Service (SNTP)

Wi-Fi Capable

Installing a new system or machine at a job site can be a painstaking process and just running cable to the new install can be an arduous task. I don't think anyone looks forward to bending and installing long conduit runs overhead, or worse, underground. Going wireless allows you to bypass new cabling issues and CLICK PLUS can help you get there easily. The CLICK PLUS C2-02CPU and C2-03CPU controllers have Bluetooth enabled by default and allow the CLICK PLUS Provisioning App to connect and quickly configure the needed Wi-Fi settings. Provisioning is usually done once and involves the process of preparing and equipping the CLICK PLUS PLC network settings to allow a temporary connection to the user's network. This removes the need for network cables and the headaches involved with new cable runs. Not only do select CLICK PLUS CPUs provide Wi-Fi capability, but with Bluetooth provisioning your system/machine will be on the wireless network and communicating in less than 30 seconds!

4 simple steps and you're all set! Now you can start up your system ahead of schedule, do some extra code verification, move on to another project or head to the break room, either way you've got time to spare with CLICK PLUS.

Get it on Google PlayDownload on the App Store

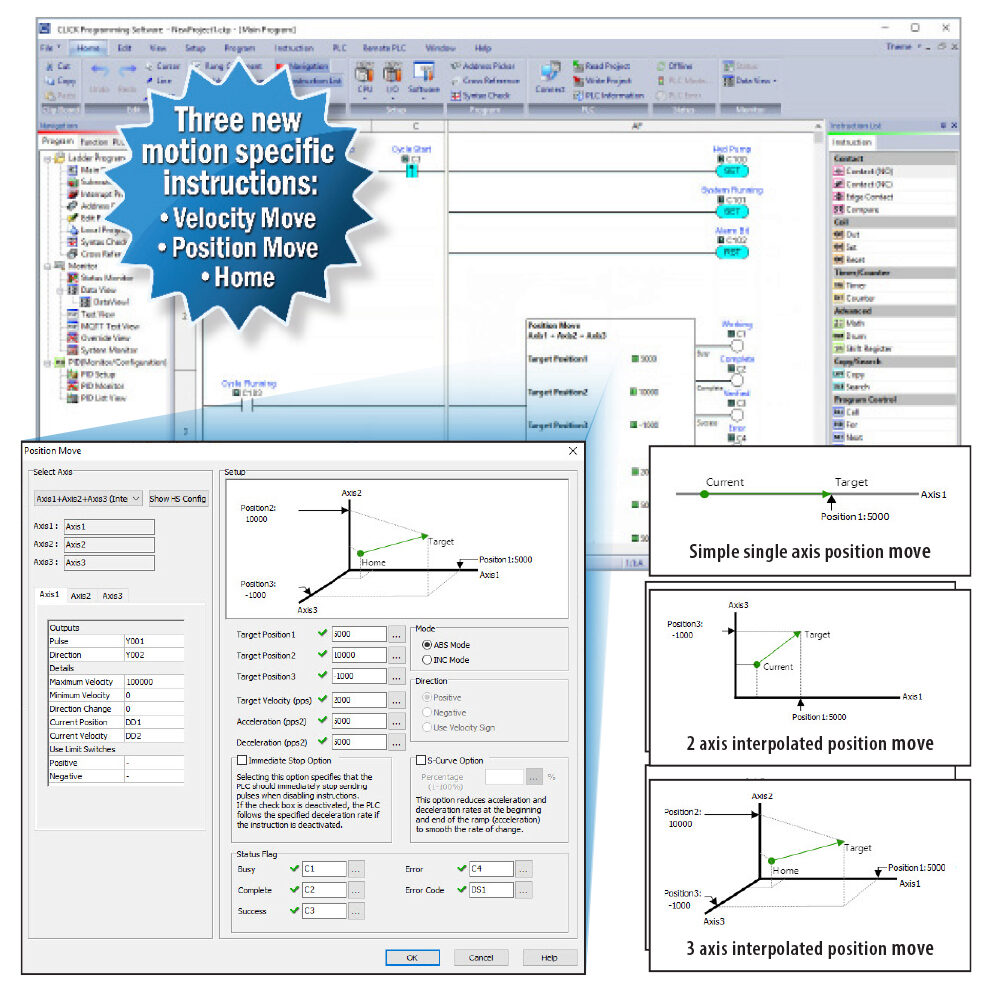

Motion this easy and affordable is soooo sweet!

CLICK PLUS is designed to make difficult tasks a cinch and every new feature must adhere to this design principle. Adding motion control to the CLICK PLUS PLC meant that it had to be simple to configure and program. First, we created an easy-to-use interface for configuring high-speed I/O. Using this interface, it only takes three steps to turn a CLICK PLUS PLC into a 3-axis motion controller:

1) From the High-speed Configuration GUI, select your high-speed input and/or output modes.

2) If your mode selection in Step 1 has more than one option (ex: up, down, up and down, and quadrature options for high-speed counters), choose which option you need and assign the number of axis required.

3) Assign your attributes to the selected mode. This includes settings like maximum velocity, pulse output address, and filtering parameters (if enabled). Once you have those set, you are ready to program.

3-Axis PTO/PWM Motion Controller

Starting at only $110.00 (C2-01CPU) + $66.00 (C2-14D1)

The FREE CLICK PLUS programming software provides three motion instructions for building your profiles. Velocity Move, Position Move and Home instructions cover a majority of simple motion control applications that this controller is geared for. Each instruction has detailed information on the profile?s parameters and even provides a graphical view of the configured profile. The Position Move instruction will also allow the use of interpolation with 2 or more axis.

Output Pulse Modes

- Up to 3-axis

- Up to 3 PTO linear step/direction outputs

- Up to 3 PWM pulse width modulation outputs

Axis Profiles

- Relative/absolute positioning

- Velocity mode

- Trapezoid

- S-Curve

- Registration

- Homing

- Jogging

- Linear Mode

Add the C2-14TTL module to your CLICK PLUS CPU for low-voltage (~5VDC), high-speed motion control signals.

For easy IIoT, CLICK PLUS is a must!

The IIoT (Industrial Internet of Things) has taken plant-floor data to new frontiers. But it all starts with the sensor, transducer, or I/O device that is detecting process information and the controller that is gathering this information, refining it as needed, and transmitting it for upstream analysis or to remote access platforms. While some IIoT capable systems can be quite costly and complex, CLICK PLUS provides the needed data gathering, data refining and protocols for IIoT applications but with simplicity and at a minimal cost to you.

Multiple data gathering options

CLICK PLUS offers many I/O options to choose from for your system data collection. The CPU option slot(s) and the numerous stackable I/O modules, available in analog, discrete, high-speed, relay, temperature, and combination modules, provide for many custom I/O configurations. And with Modbus RTU, Modbus TCP and EtherNet/IP protocol support, CLICK PLUS can easily gather raw data from a variety of VFDs, sensors, switches, encoders, pilot devices, or almost any other control component your system may have.

Refining data into something meaningful

The CLICK programming software makes refining raw data into a meaningful metric a cinch. From CLICK's simple scaling function for analog signals, to streamlined PID loops with easy step-by-step configurations, to the super simple instructions, CLICK will easily transform a raw process signal, like 4-20mA, into a consumption rate, an energy efficiency score, a rejection percentage, or any other metric that's vital to you.

Make your system IIoT capable for only $110.00!

With the explosion of Ethernet connectivity in the industrial realm and the resulting expansion of smart devices, cloud platforms and mobile networking, modern-day controllers are expected to support the protocols needed for these new technologies. The MQTT protocol has become the frontrunner for many of these machine-to-machine (M2M) and IIoT/cloud applications, due to its lightweight overhead and reduced bandwidth consumption. All of the low-cost CLICK PLUS CPUs provide MQTT communication, via Ethernet or wireless means, allowing even the simplest, most inexpensive systems to become IIoT capable.

On the PLUS side, you're more secure than ever before

With increasing concern and interest for the security of PLC's, there is a growing need to integrate security directly into the PLC itself. The CLICK PLUS offers several different security features designed to minimize PLC vulnerabilities.

1. Secure PLC Access

The CLICK PLUS PLC ships from the factory with a default username and password, however the first time a user connects to the PLC, they will be required to input a unique password or disable the PLC login password if desired. Forcing this change helps greatly reduce the chances of malicious software taking control of the PLC with easy-to-guess or publicly disclosed default login credentials.

2. Strong password support

The CLICK PLUS PLC supports strong passwords to allow for more secure PLC projects and data files. Only qualified passwords are allowed, and the software offers feedback on the strength of the password while the User account is being configured.

3. Disable PING response

Users can configure the PLC Ethernet RJ45 and Wi-Fi network ports to ignore PING requests from other devices. This makes the PLC invisible to pings and thus reduces the vulnerability to deliberate denial of service (DoS) attacks.

4. Improved port management

Users can disable all non-essential RJ45, Wi-Fi and Bluetooth ports as needed to reduce the vulnerability of unauthorized access.

5. Encrypted password transfer/storage

Encryption helps to protect project sensitive passwords from being hacked while being transferred over the network or stored in the PLC.

6. Secure email with TLS

Send secure emails with the CLICK PLUS Email instruction. This instruction allows for multiple recipients and customizeable messages capable of sending dynamic data. The Email command utilizes Transport Layer Security (TLS) which is a cryptographic protocol that secures communication over a network by encrypting the connection between computers.

7. Allow List

The Allow List is used to explicitly allow certain other devices to communicate with the CLICK/CLICK PLUS CPU. This feature is supported by CLICK Ethernet (C0-1x) and CLICK PLUS (C2-x) CPUs.

8. Event Records

Logging the connection activity of the CLICK/CLICK PLUS CPU allows you to monitor for suspicious activity. Event records are stored for password attempts, Allow List rejections, and email activity (CLICK PLUS only).

9. Session-based software connections

The CLICK PLUS PLC platform utilizes session-based communication on the Wi-Fi and Ethernet ports. By using sessions, each initiated communication request must contain a unique ID. If the ID is missing, the CLICK PLUS PLC will discard the request. This allows only authorized access and helps prevent PCs from accessing the wrong PLC. Sessions will also time out if not utilized, closing the idle link between the programming software and the PLC which must be reestablished if needed.

The session ID is also used to limit the software session to only one simultaneous session at a time which removes the chances of multiple remote users making changes to the PLC project at the same time. If someone tries to log into a PLC that already has an active session, the software will notify the user that there is an existing software connection currently logged in.

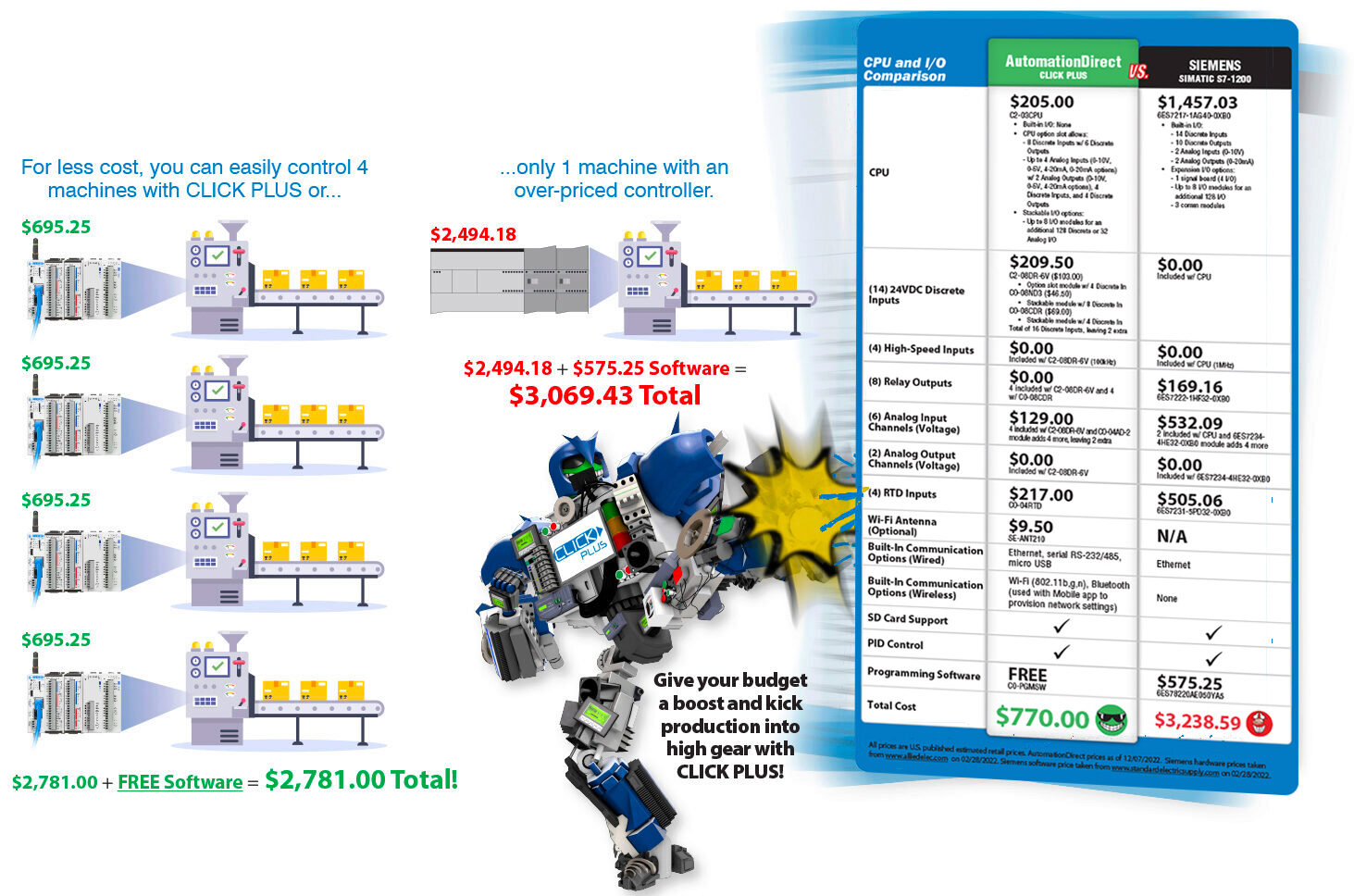

CLICK PLUS turns low budget...into mo' budget!

Let's face it, there are some systems that require controllers capable of extremely complex logic operations, but there are also times when these controllers are way over advanced and way over budget for the job at hand. When you just need a simple control solution to get the job done quickly, don't pay thousands for a controller with features you'll never use. Instead, save those thousands and get a controller designed with simplicity in mind, one that's one-quarter the price of other PLCs, and one that comes with some surprising capabilities you wouldn't expect at this price range including Wi-Fi connectivity, high-speed I/O, data logging and more!

Process Control built with ease

The CLICK PLC family is the lowest cost, easiest to use PLC in the market today and now we've added to it the most user-friendly PID process control. We streamlined CLICK's PID control and included only the features that most users need. We also made the PID configuration more visual with easy to follow steps to help guide you and get your parameters set quickly.

Not only is the CLICK PID simple, but with the ability to configure up to 8 PID control loops executing every 100ms, CLICK provides the most affordable PID available.

We do most of the work for you

From the first (General) tab we make it easy by giving you the option to automatically reserve the addresses needed for the configuration and operation of the PID loop. Intuitive Nicknames are also created automatically for you so that selecting the address you need in your code is quick and simple.

Throughout the configuration, we guide you to the parameters that need to be set using red checkmarks, green checkmarks are ready to go, and yellow are optional parameters.

CLICK PID comes with all the basic PID functions plus these advanced options:

- Setpoint Limits

- Process Variable Filter

- Control Output Limits

- Error Squared

- Error Deadband

- Anti-windup

- Derivative Gain Limit

- Bumpless Transfer

- Autotuning

- Direct or Reverse Acting

- Pulse width modulated Control Output

- Process Variable Alarms

- PID Monitor

PID monitoring and auto-tuning

PID monitoring and auto-tuning

The CLICK PID Monitor is a very useful tool which can be used to help test and tune your PID loops. The PID Monitor gives access to all the PID parameters necessary for tuning a PID Loop. There is a PID chart that displays the SP, PV's, CO and Bias. There is also an auto-tune interface that allows you to set up and initiate auto-tuning.

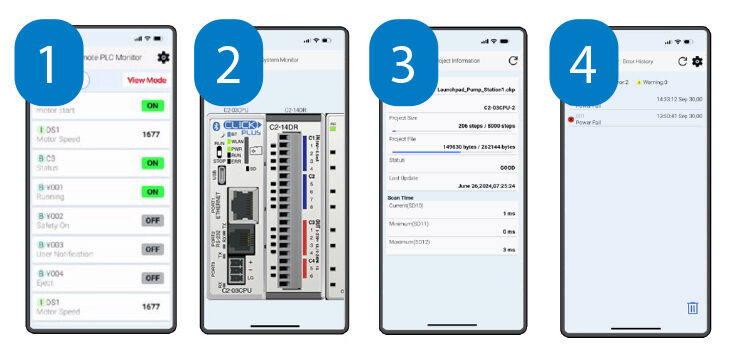

FREE CLICK Remote PLC Mobile App

The CLICK Remote PLC mobile app offers a convenient way to view and edit values in select CLICK Ethernet or CLICK PLUS PLC registers. With the mobile app, you can also check PLC project/status information, including data stored in error logs.

Features:

- Multiple level user accounts - once connected, the authorized users can view and edit PLC values based on their permission levels set up in the project file.

- Custom Monitor windows can be created and stored to the PLC using the CLICK programming software version 3.60 or later.

- Monitor and edit designated discrete and numeric values within the PLC. For example, timer/counter presets can easily be viewed and edited.

- PLC status information, such as PLC error logs, scan times (min and max), as well as project file information can also be viewed.

Use the CLICK Remote PLC Mobile App with:

- CLICK Ethernet PLCs or CLICK PLUS PLCs and a WiFi router

- CLICK PLUS PLCs using Bluetooth

Use the CLICK Remote PLC Mobile App to:

- View and edit values in the PLC registers

- Use the System Monitor to see LED status and analog data

- Check the PLC project information

- See the PLC error log data

Startups made easier!

Most, if not all, of us have been on startups, testing the numerous inputs wired to the main PLC cabinet. This usually involves two or more people - one to flag the sensor in the field and the other to watch the input on the PLC. This can be a real headache especially when there are multiple sensors scattered all throughout the facility or if the system is located in a noisy environment where it's hard to communicate. With the CLICK Remote PLC mobile app, only one person is needed to check each input. Simply open the app, connect to the CLICK PLC, flag each sensor, and watch the input change remotely on your mobile device. With the app, input verification is so much quicker and easier!

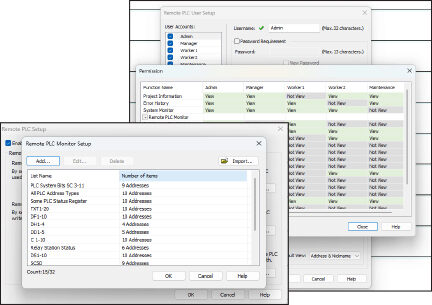

Configure what can be seen and by whom

All of the PLC values that will be available through the app and who gets to view and edit them, are configured in the user-friendly CLICK PLC programming software. There you will find convenient dialogs for adding PLC values to the remote monitor list and for adding several users, each with their own permission levels and allowed actions.

FREE Software that's Simple to Learn & Easy to Use

We listened to our customers to create a simple, intuitive programming environment. The CLICK PLC Programming Software is based on the C-more & C-more Micro programming environment. We leveraged these two great programming packages and created the latest in our line of intuitive programming tools, and then made it a FREE download from our website. So you can have free software for your practically free PLC!

But don’t let the $0.00 price tag fool you - you'll find this software to be loaded with options that you would normally expect to pay extra for!

This includes a more intuative instruction set that is easier to use and extremely functional at the same time. We have worked to create one of the best help files of any software in the industry and we strived to provide the user enough options to easily address all phases of programming (learning, coding, commissioning, troubleshooting).

Get FREE online training with our official training provider: InterConnecting Automation (ICA). ICA's professional trainers have been teaching our customers about PLCs, Motors & Drives, and other automation topics for years. Recently they have been developing an extensive online video library on these topics and more. Watch as many of these videos as you like - on your schedule.

ICA has over 75 videos dedicated to CLICK alone, and hundreds more on other topics and PLC families.

Check out the Free PLC training here.

Simple Instructions

Intuitive Instruction Set

Intuitive Instruction Set

The CLICK PLC programming software offers up to 25 extremely easy-to-use instructions! This instruction set offers the same flexible control you might expect from over 150 instructions in a traditional controller. Simply drag and drop these instructions onto the laddder view (the center section of the screen), and a helpful dialog box will guide you through each instruction's configuration.

8,000 Program Steps...

CLICK CPU modules can store up to 8,000 steps (instructions) of your ladder logic program in nonvolatile memory. That's more than enough for most CLICK appropriate applications.

...AND On-board Documentation

Don't need all that memory for your ladder program? You can opt to store all the documentation (your comments, tag names, etc.) on-board the CLICK CPU as well. This can be especially useful if you find yourself editing the program with a different programming PC in the future.

Math Made Easy

Math Made Easy

Check out the spreadsheet style math instruction, just enter a formula (with embedded PLC tags if you wish) and enter a "result tag". Supports all the standard scientific calculator functions. Make it a "one shot" with a simple check box. It really couldn't be any easier.

Programming Flexibility

NO Limits on Subroutines...

The ladder program can be organized into subroutines with no limit on the number of subroutines other than the total available memory.

...PLUS 8 Interrupt Routines

...PLUS 8 Interrupt Routines

Up to 8 Interrupt routines can also be defined, and can be initiated based on time interval (software interrupt) or via the discrete inputs on the CPU module (external interrupt). Interrupt routines execute immediately, causing the normal PLC scan to be paused. These are great for time-critical operations, especially if the normal scan time of the PLC is high.

Easy Installation

Easy Installation

The CLICK PLC system does not require a mounting base or rack, which saves money and space. CLICK uses only as much space as needed for a specific application

The CLICK CPU and I/O modules are connected together via an integrated expansion port on the sides of the modules and sliding locking tabs on the top and bottom of all modules.

- Remove the protective cover

- CLICK the neighboring modules together

- Slide the locking tabs to secure

CLICK mounts on standard 35mm DIN rail, or via slide-out mounting feet.

Expandable up to 156 discrete I/O

A CLICK PLUS CPU and option slot modules are a complete PLC system by itself, with different I/O configurations available, or the system can be expanded with the addition of up to eight stackable I/O modules. A variety of I/O modules are available for flexible and optimal system configuration.

View more information about

CLICK stackable I/O

CLICK PLUS option modules

DC I/O modules

AC and Relay I/O modules

Analog I/O modules

Expandable up to 142 discrete I/O

Cut your PLC wiring time down to minutes instead of hours

Cut your PLC wiring time down to minutes instead of hours

The ZIPlink wiring system eliminates the normally tedious process of wiring PLC I/O to terminal blocks. Simply plug one end of a ZIPlink pre-wired terminal block cable into your I/O module and the other end into a ZIPlink connector module. It’s that easy. ZIPlink use half the space, at a fraction of the total cost of terminal blocks.

- One ZIPlink model works with all CLICK PLC Units, stackable I/O modules, and most CLICK PLUS CPU Option Slot Modules

- Two ZIPlink Cable styles...

- And three Cable lengths available

Learn more about the CLICK ZIPlink options here.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...