Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

FedEx orders placed before 4:00PM ET on Thursday, April 17th will ship same day. Freight & UPS orders have a 1:00PM ET cutoff. Orders placed after the Thursday cutoff will ship Monday, April 21st.

Note: Due to the Friday holiday, we will not be able to ship next day orders for Saturday or Monday delivery.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wiring Solutions

- Retired Products

- Programmable Logic Controllers

- Productivity1000 PLCs

- Productivity2000 PLCs

- Productivity3000 PLCs

- ProductivityCODESYS

- LS Electric XGB Series PLCs

- ProductivityOpen

- CLICK PLCs

-

Do-more H2 PLCs or

Do-more T1H Series - Do-more BRX PLCs

- C-more Touch Panels

- AC & DC Drives

- Motion Control Components

- Servos

- StrideLinx

- Pneumatics

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- AC Motors

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

Terminal blocks provide easy connection of panel-mounted electronic components to device power and field wiring. A wide variety of modular terminal blocks are available in various styles and specialized purposes to make quick, clean, safe and efficient installations.

This page will refresh momentarily.

Warning

Some of the selected facets have been selected by the {{ assistanceData.title }} Help.

Resetting/clearing ALL facets will end {{ assistanceData.title }} Help.

![Help icon]() Selection Assistance - {{ assistanceData.title }}

Selection Assistance - {{ assistanceData.title }}

Stride Interactive Product Tour Request

Terminal Blocks

Category Selection

- Single-level Feed-through Terminal Blocks

- Double-level Feed-through Terminal Blocks

- Triple-level Feed-through Terminal Blocks

- Mini Terminal Blocks

- Common Point Terminal Blocks

- Grounding Terminal Blocks

- Circuit Protection Terminal Blocks

- Disconnect Terminal Blocks

- Plug-In Terminal Blocks

- Thermocouple Terminal Blocks

- Mini Supplementary Protectors

- Terminal Plugs

- End Brackets

- End Covers

- Separators

- Top Covers

- Jumpers

- Marking Tags

- Terminal Block Accessories

Terminal blocks are insulated modular blocks that connect two or more wires together. Basic terminal blocks consist of a wire clamping mechanism for each wire with a conductive metal strip between them. Terminal blocks provide secure connections, easier wire installation/removal, and better organization than other connection methods. Several varieties of terminal blocks are available, many for specific purposes, across the brand/series offered.

- Konnect-It screw-type terminal blocks offer cost-effective components that fit on a 35mm DIN rail (standard terminal blocks), or 15mm DIN rail (mini terminal blocks)

- DINnectors screw-type terminal blocks offer the most expansive selection of terminal block styles and connection options. They are internationally approved by national and international standards organizations such as UL, CSA, VDE, SEV, RINA and IEC.

- DINnectors screwless type terminal blocks use a spring clamping system for wire connection. They offer a quick and easy clamping system that is secure and maintenance free. Just push the spring clamp, insert the wire and release. This series offers a functional set of block types that support most applications.

Terminal blocks are sold in cost-saving multi-packs of up to 100, or in convenience packs of lower quantities, depending on part number.

For part listings and specifications, go to Shop Now

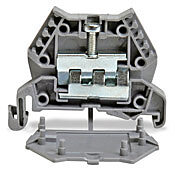

Single-level Feed-through Terminal Blocks

Single-level feed-through terminal blocks are the simplest type of terminal block, designed to support one input and one output connection. They are available in various colors, wire size options, and other features, depending on series.

- Konnect-It KN series screw type: up to 175A, wire sizes up to 2/0 AWG

- DINnectors DN series screw type: up to 185A, wire sizes up to 3/0 AWG

- DINnectors DN series screwless type: up to 45A, wire sizes up to 8 AWG

Double-level Feed-through Terminal Blocks

Double-level feed-through terminal blocks allow space savings by providing two independent connection terminals in a single block. They are available in various colors and wire size options, depending on series. Certain series are available with an optional LED indicator and other features.

- Konnect-It KN series screw type: up to 30A, wire sizes up to 10 AWG

- DINnectors DN series screw type: up to 30A, wire sizes up to 10 AWG

- DINnectors DN series screwless type: up to 20A, wire sizes up to 12 AWG

Triple-level Feed-through Terminal Blocks

Triple-level feed-through terminal blocks provide three connection terminals for even more space savings, available in various colors, wire size accommodation and other options, depending on series.

- Konnect-It KN series screw type: up to 24A, wire sizes up to 12 AWG

- DINnectors DN series screw type: up to 10A, wire sizes up to 14 AWG

Mini Terminal Blocks

Mini terminal blocks are used in areas with extremely limited space requirements and are only mountable on 15mm DIN rails.

- Konnect-It KN series screw type: up to 30A, wire sizes up to 10 AWG

- DINnectors DN series screw type: up to 10A, wire sizes up to 10 AWG

Common Point Terminal Blocks

Common point terminal blocks are designed for applications requiring multiple wires to be tied together. They are available in one-to-two or two-to-two configurations and utilize multiple spring clamps that are all connected to a singular internal conductive strip. LED and diode variations are also available.

- DINnectors DN series screwless type: up to 20A, wire sizes up to 12 AWG

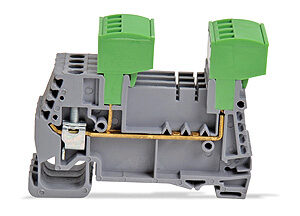

Grounding Terminal Blocks

Grounding terminal blocks are used to electrically connect wires to the DIN rail by means of a conducting clamping foot. In this way, the DIN rail can function as a ground bus bar. Grounding terminal blocks offer low contact resistance, corrosion-free connection points, and feature an easily identified yellow-green colored housing.

- Konnect-It KN series screw type: wire sizes up to 8 AWG

- DINnectors DN series screw type: wire sizes up to 1/0 AWG

- DINnectors DN series screwless type: wire sizes up to 8 AWG

Circuit Protection Terminal Blocks

Circuit protection terminal blocks, sometimes referred to as fused terminal blocks, utilize replaceable fuses or circuit breakers/disconnects for the connection between the attached wires. Various models are available for fuses, circuit disconnects, or supplementary circuit breakers.

- Konnect-It KN series screw type: up to 6.3A, wire sizes up to 8 AWG

- DINnectors DN series screw type: up to 10A, wire sizes up to 6 AWG

Disconnect Terminal Blocks

Disconnect terminal blocks are a simple solution when the circuit wired to the terminal block needs to be opened on occasion for maintenance, etc. or to perform tests while the system is powered. Disconnection may be via moveable jumper bar or pivoting knife blade, depending on series.

- Konnect-It KN series screw type: up to 16A, wire sizes up to 8 AWG

- DINnectors DN series screw type: up to 25A, wire sizes up to 10 AWG

- DINnectors DN series screwless type: up to 20A, wire sizes up to 12 AWG

Plug-In Terminal Blocks

Plug-in terminal blocks support connectors/plugs (sold separately) that can be removed, wired with the desired connections, and inserted back into the terminal block.

- DINnectors DN series screw type: up to 12A, wire sizes up to 12 AWG

- DINnectors DN series screwless type: up to 12A, wire sizes up to 12 AWG

Thermocouple Terminal Blocks

Thermocouple terminal blocks are designed with only one screw clamp to provide suitable connections for thermocouple sensors. These clamping yoke terminal blocks will accept any type of thermocouple lead connection within their rated wire size range, providing excellent continuity without the need for any other compensation metals/contacts.

- DINnectors DN series screw type: 50V AC/DC or 300V ratings, wire sizes up to 18 AWG

Mini Supplementary Protectors

Mini supplementary protectors are used with select circuit protection terminal blocks to add supplementary protection to any circuit quickly and easily.

- 0.25 to 10A amperage rating

- UL 1077 single pole push ON, push OFF, push to reset versions

- For DINnectors screw-type terminal blocks

Terminal Plugs

Terminal plugs (aka terminal plugs) are used for plug-in terminal blocks to provide various terminal connections.

- Available with up to 12 terminal connections

- 300V / 12A rated

- Wire sizes 14 to 22 AWG

- For DINnectors screw-type and screwless terminal blocks

End Brackets

End brackets prevent terminal blocks and other DIN rail mount components and devices from moving laterally on the rail.

- Constructed from polyamide 66

- Available for 35mm and 15mm DIN rails, depending on series

- Available for Konnect-It and DINnectors series terminal blocks

End Covers

End covers are used to cover the open side of DIN-rail mounted terminal blocks, providing a protection barrier from potential electrical hazard. They should be used at the end of an assembly of identical terminal blocks or whenever there is a change in the physical size of the terminal block.

- Constructed from polyamide 66

- Selection of shapes and colors, depending on series

- Available for Konnect-It and DINnectors series terminal blocks

Separators

Separators are used to segment banks of terminal blocks, making it possible to maintain a single row of terminal blocks while having separate power source clusters.

- Selection of colors and dimensions, depending on series

- Available for Konnect-It and DINnectors series screw-type terminal blocks

Top Covers

Top covers snap on top of terminal blocks to prevent accidental contact with personnel or other equipment.

- Available in various designs with printed symbols or blank to allow labeling or marking, depending on series

- Available for Konnect-It and DINnectors series screw-type terminal blocks

Jumpers

Jumpers provide quick and easy connections between terminal blocks.

- Styles include screw-down connection or screwless comb-style jumpers

- Various pole quantities and configurations

- Available for Konnect-It and DINnectors series screw-type terminal blocks

Marking Tags

Marking tags provide identification of terminal blocks and wires. Tags are available either blank or in various preprinted designs.

- Available for Konnect-It and DINnectors series terminal blocks

Terminal Block Accessories

Terminal block accessories to aid in installation include:

- Label holders

- Disconnect knife blade inserts

- Wire tag holders

- A selection of special cutting pliers

- Terminator block tool kit

- Test plugs

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings