Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

View FedEx Service Alerts for updated information. We apologize for the inconvenience this weather issue may cause.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wire & Cable Management

- Wire & Cable Termination

- Retired Products

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Pyrometers Selector

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

Use our configuration tool to configure and order.

The Productivity3000 PLC provides the expansive I/O, robust communication, integrated data storage, and processing power needed for complex automation systems. A wide range of discrete, analog, and motion modules is available for systems up to 59,000 I/O points, depending on module mix.

This page will refresh momentarily.

Warning

Some of the selected facets have been selected by the {{ assistanceData.title }} Help.

Resetting/clearing ALL facets will end {{ assistanceData.title }} Help.

![Help icon]() Selection Assistance - {{ assistanceData.title }}

Selection Assistance - {{ assistanceData.title }}

Stride Interactive Product Tour Request

CPUs

Remote I/O

Expansion I/O

Bases

Power Supplies

DC I/O

AC I/O

Relay Output

Analog I/O

Communications & Networking

Motion & Specialty Modules

ZIPLink Wiring Solutions

Productivity3000 Accessories

Productivity3000 Modular PLC

Category Selection

The Productivity3000 PLC series is the I/O leader of the family with over 59,000 I/O points possible. This rack-based controller provides an abundance of networking options with numerous built-in communication ports along with many other great features. (For small footprint, see the Productivity1000 series. For the sweet spot of cost and features, see the Productivity2000 series.)

- High-performance CPU with up to 50MB of user memory

- 7 communication ports including USB, Ethernet, RS-232, RS-485

- Support for Modbus RTU/TCP, EtherNet/IP and MQTTS communication

- LCD message display on CPU module and real-time data displays on all analog I/O modules

- USB data logging

- Full lineup of discrete, analog, and specialty I/O modules

- Auto-discover I/O modules, GS drives, Protos X I/O and PS-AMC motion controllers

- No module placement restrictions, no power budget limitations

- Easy coordinated motion control using PS-AMC motion controllers

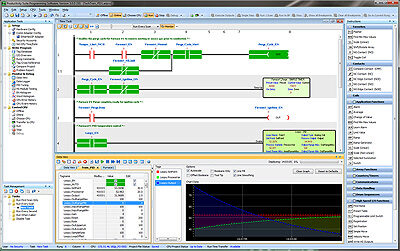

The FREE Productivity Suite programming software provides the freedom to define user tags with no limits or fixed boundaries. Configure timers, counters, integer words or any other data types needed. With tag name based programming, there are no pre-defined, fixed memory maps and no wasted memory. Productivity Suite also provides many convenience features including a project simulator for code verification, EDS file support, advanced user defined structures, and easy "fill-in-the-blank" instructions to make project development quick and simple.

For part listings and specifications, go to Shop Now

CPUs

Newest Additions!

- P3-622 next generation CPU

The Productivity3000 controller CPU contains the processing, memory, and I/O interface needed to perform logic operations, networking tasks, and many other functions required in an automated control system. This CPU features multiple communications ports, an LCD status display, 50 MB of user memory, USB data logging, and much more.

Remote I/O

The Productivity3000 PLC remote I/O module can simplify system architecture and reduce wiring costs when I/O must be located away from the local CPU. Remote I/O modules can also be used to increase the I/O capacity of the system. By adding up to 16 remote I/O bases to the local base group using the CPU's Remote I/O Ethernet port, tens of thousands of additional I/O points can be added.

Expansion I/O

Productivity3000 expansion I/O modules use USB-based communication to add extra I/O to the local PLC or to each remote I/O module. Up to 4 expansion groups can be daisy chained together using the USB IN/OUT ports of the expansion module for up to 68 total expansion bases in a system (4 per CPU, 4 per remote base).

Bases

A PLC base unit provides a means of housing the power supply, CPU or remote I/O module, and connecting to the installed I/O. Modular base units supply slots for interchangeable I/O connections to the backplane's data bus. Productivity3000 modular base units contain both DIN-rail and flush-mount options with various slot capacities.

Power Supplies

Power supplies provide the DC power needed for proper controller operation. Productivity3000 power supplies are available in DC or AC input versions and can be used with in a base with any I/O module combination with no power budgeting requirements.

DC I/O

DC I/O modules monitor ON/OFF signals or control devices that switch DC power and are available in a wide variety of 8-point, 16-point, 32-point, and 64-point versions.

AC I/O

AC I/O modules monitor and control ON/Off type devices that operate with AC power (100-240 VAC) and are available in input or output models with up to 16 points.

Relay Outputs

Relay modules provide surge-protected outputs to operate DC or AC rated devices (6-24 VDC / 6-240 VAC) and are available with Form C (normally open/normally closed) and/or Form A (normally open) relay contacts, with up to 16 points.

Analog I/O

Analog input and output modules are available to monitor and control pressure, temperature, flow, level, and other process signals. Modules are offered in high-resolution current, voltage, and temperature models with helpful LCD real-time data displays.

Communications & Networking Modules

The Productivity3000 CPU has numerous built-in communication ports to handle most application needs. However, optional networking modules are available that can provide protocol conversions or additional serial ports.

Motion & Specialty Modules

Motion and specialty modules are designed to perform specific functions, including input simulation and high-speed counting. If enhanced motion capabilities are required, the PS-AMC motion controller can be used with certain CPUs for coordinated motion on up to four axes.

ZIPLink Wiring Solutions

The ZIPLink connection module and cable system eliminates the normally tedious process of wiring programmable controller I/O to terminal blocks.

Productivity3000 Accessories

Accessories for the Productivity3000 PLC system include I/O module terminal blocks, ProductivityMotion connector kit, replacement fuses, and USB cables. The powerful, easy-to-use, tag name-based Productivity Suite software can be downloaded for free; a software USB drive is available for purchase if needed.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...