Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

We will close at 3PM ET on Tuesday, December 23rd. Please note our shipping changes for Tuesday.

Freight shipments, FedEx ground and customer pickup deadline is 11:00AM ET. FedEx Priority (and free 2-day delivery) cutoff will be 1:00 PM ET. No UPS shipping will be available on Tuesday.

Drop ship vendors, Saginaw, Husky and Weigmann will also be closed Friday, Dec 26th.

Merry Christmas to each of you and your families from the employees of AutomationDirect

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wire & Cable Management

- Wire & Cable Termination

- Retired Products

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Pyrometers Selector

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

The Almost Free PLC that's so simple, we named it CLICK®.

All PLCs Should be this Flexible and Convenient

CLICK® CPU modules start at $104.00. You get a ton of control for your automation buck.

Use a CLICK CPU as a standalone PLC...

The Basic & Standard CPU's have eight discrete inputs and six discrete outputs built-in. The Analog and Ethernet Analog CPUs have 4 discrete inputs, 4 discrete outputs, as well as 2 or 4 analog inputs and 2 analog outputs.All these DC powered PLCs are mighty controllers as stand alone units, or you can expand the I/O count with up to 8 modules for up to 142 total discrete I/O points and 54 analog I/O channels!

CLICK offers flexible power options

With multiple options for main input power, this flexible unit allows you to decide what best fits in your control cabinet. Use your existing 24VDC power supply (if applicable), select one of our low cost CLICK PLC power supplies (based on your system power budget requirements) or select one of AutomationDirect’s rugged Rhino power supplies.

CLICK to save space and time

CLICK modules lock together for easy installation. CLICK is 'rackless', saving valuable panel space by occupying only as much DIN rail length as required for your application. Zip-link modules cut your PLC wiring time down to minutes instead of hours, and can save you hundreds of dollars on terminal blocks and labor.

...expand CLICK for more complex applications

The I/O line-up includes 28 modules to choose from, including both sinking & sourcing 24VDC input & output options, 120VAC input & output modules, and relay modules for those applications requiring a little more power.

Need a matching HMI?

Need a matching HMI?

CLICK is a perfect match for C-more Micro, we designed them to work together. Both are an excellent value. And a single, inexpensive cable supplies power and communication.

CLICK plays nicely with others

Two (2) RS-232 communications ports supporting industry standard MODBUS RTU protocol are included on all units. Standard, Ethernet Standard, Analog and Ethernet Analog models also include an RS-485 port for even more connectivity. These ports are suitable for connection to a PC for programming, networking PLCs, C-more/C-more Micro operator interface panels, variable frequency drives, servos, steppers, and any other MODBUS-enabled devices.

Our most practical PLC

The CLICK PLC is annother great product which compliments their already stellar line-up of PLCs. With a starting price of $104.00 for a CPU w/ 8 built-in digital inputs & 6 built-in digital outputs, this stand alone, Micro Brick PLC is by far the most practical PLC for the money.

Choose from

thirty-one CPU Models

with various I/O types

Optional

Power Supplies

and

Option Modules

allow expansion up to 142 discrete I/O points

Get Connected FAST with just a simple CLICK!

Low-cost Ethernet!

Low-cost Ethernet!

The CLICK Ethernet PLC units come with a 10/100 Mbps multipurpose Ethernet port for faster networking and control. Use the built-in Ethernet port to program your system, network your CLICK, or control Ethernet-enabled end devices. Using the Modbus TCP Client/Server and EtherNet/IP Adapter Server protocols, the new CLICK PLCs will easily integrate into existing networks and provide a simple, cost effective solution for your application.

Connect multiple Modbus TCP Clients/Servers as well as up to two EtherNet/IP Adapter Server connections to the CLICK Ethernet PLC models. These models also offer a serial port that can be used for Modbus RTU connections. Making this a perfect unit for a low-cost, highly capable control system.

Run Time Edits

The PLCs not only allow for faster connections but they also come with more memory. The added memory size gives CLICK the ability to perform run-time edits on live machinery and/or processes. This feature can greatly reduce unnecessary downtime and is an important addition to an already extremely practical PLC.

AND Faster Execution

Along with improved communication speed, CLICK Ethernet PLCs are capable of executing logic 3 to 10 times faster than before. Nowhere else will you find this level of performance at this low of a price!

Watch videos:

Watch videos:

"Introducing the Ethernet PLC Units"

High-speed Counter/Timer Inputs

CLICK Ethernet PLC units with DC inputs also offer high-speed functionality capable of handling input pulse frequencies up to 100kHz. Easily count and/or calculate pulse rates from dedicated inputs or encoder signals that are used in many applications including package tracking and picking systems.

High-speed Input Configuration

High-speed Input Configuration

High-speed input functions including pulse counting and frequency measurements are made simple with the user-friendly graphical user interface (GUI). Simply choose the desired high-speed function and the interface will guide you through the available features and options.

Process Control built with ease

The CLICK PLC family is the lowest cost, easiest to use PLC in the market today and now we've added to it the most user-friendly PID process control. We streamlined CLICK's PID control and included only the features that most users need. We also made the PID configuration more visual with easy to follow steps to help guide you and get your parameters set quickly.

Not only is the CLICK PID simple, but with the ability to configure up to 8 PID control loops executing every 100ms, CLICK provides the most affordable PID available.

We do most of the work for you

From the first (General) tab we make it easy by giving you the option to automatically reserve the addresses needed for the configuration and operation of the PID loop. Intuitive Nicknames are also created automatically for you so that selecting the address you need in your code is quick and simple.

Throughout the configuration, we guide you to the parameters that need to be set using red checkmarks, green checkmarks are ready to go, and yellow are optional parameters.

CLICK PID comes with all the basic PID functions plus these advanced options:

- Setpoint Limits

- Process Variable Filter

- Control Output Limits

- Error Squared

- Error Deadband

- Anti-windup

- Derivative Gain Limit

- Bumpless Transfer

- Autotuning

- Direct or Reverse Acting

- Pulse width modulated Control Output

- Process Variable Alarms

- PID Monitor

PID monitoring and auto-tuning

PID monitoring and auto-tuning

The CLICK PID Monitor is a very useful tool which can be used to help test and tune your PID loops. The PID Monitor gives access to all the PID parameters necessary for tuning a PID Loop. There is a PID chart that displays the SP, PV's, CO and Bias. There is also an auto-tune interface that allows you to set up and initiate auto-tuning.

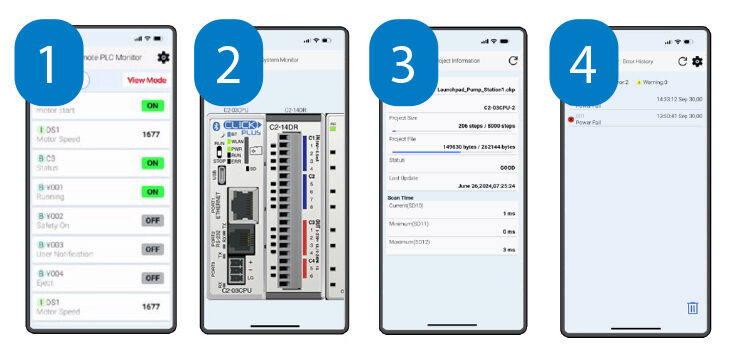

FREE CLICK Remote PLC Mobile App

The CLICK Remote PLC mobile app offers a convenient way to view and edit values in select CLICK Ethernet or CLICK PLUS PLC registers. With the mobile app, you can also check PLC project/status information, including data stored in error logs.

Features:

- Multiple level user accounts - once connected, the authorized users can view and edit PLC values based on their permission levels set up in the project file.

- Custom Monitor windows can be created and stored to the PLC using the CLICK programming software version 3.60 or later.

- Monitor and edit designated discrete and numeric values within the PLC. For example, timer/counter presets can easily be viewed and edited.

- PLC status information, such as PLC error logs, scan times (min and max), as well as project file information can also be viewed.

Use the CLICK Remote PLC Mobile App with:

- CLICK Ethernet PLCs or CLICK PLUS PLCs and a WiFi router

- CLICK PLUS PLCs using Bluetooth

Use the CLICK Remote PLC Mobile App to:

- View and edit values in the PLC registers

- Use the System Monitor to see LED status and analog data

- Check the PLC project information

- See the PLC error log data

Startups made easier!

Most, if not all, of us have been on startups, testing the numerous inputs wired to the main PLC cabinet. This usually involves two or more people - one to flag the sensor in the field and the other to watch the input on the PLC. This can be a real headache especially when there are multiple sensors scattered all throughout the facility or if the system is located in a noisy environment where it's hard to communicate. With the CLICK Remote PLC mobile app, only one person is needed to check each input. Simply open the app, connect to the CLICK PLC, flag each sensor, and watch the input change remotely on your mobile device. With the app, input verification is so much quicker and easier!

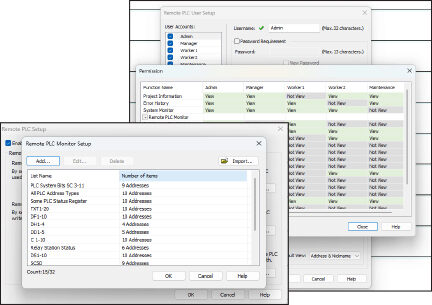

Configure what can be seen and by whom

All of the PLC values that will be available through the app and who gets to view and edit them, are configured in the user-friendly CLICK PLC programming software. There you will find convenient dialogs for adding PLC values to the remote monitor list and for adding several users, each with their own permission levels and allowed actions.

FREE Software that's Simple to Learn & Easy to Use

We listened to our customers to create a simple, intuitive programming environment. The CLICK PLC Programming Software is based on the C-more & C-more Micro programming environment. We leveraged these two great programming packages and created the latest in our line of intuitive programming tools, and then made it a FREE download from our website. So you can have free software for your practically free PLC!

But don’t let the $0.00 price tag fool you - you'll find this software to be loaded with options that you would normally expect to pay extra for!

This includes a more intuative instruction set that is easier to use and extremely functional at the same time. We have worked to create one of the best help files of any software in the industry and we strived to provide the user enough options to easily address all phases of programming (learning, coding, commissioning, troubleshooting).

Get FREE online training with our official training provider: InterConnecting Automation (ICA). ICA's professional trainers have been teaching our customers about PLCs, Motors & Drives, and other automation topics for years. Recently they have been developing an extensive online video library on these topics and more. Watch as many of these videos as you like - on your schedule.

ICA has over 75 videos dedicated to CLICK alone, and hundreds more on other topics and PLC families.

Check out the Free PLC training here.

Simple Instructions

Intuitive Instruction Set

High Speed Output and Email instructions only available with CLICK PLUS PLCs

Intuitive Instruction Set

The CLICK software includes a more intuitive instruction set that is easier to use and extremely functional at the same time. We used Decimal Addressing and preassigned MODBUS addresses. We have worked to create one of the best help files of any software in the industry and we strived to provide the user enough options to easily address all phases of programming (learning, coding, commissioning, troubleshooting).

8,000 Program Steps...

CLICK CPU modules can store up to 8,000 steps (instructions) of your ladder logic program in nonvolatile memory. That's more than enough for most CLICK appropriate applications.

...AND On-board Documentation

Don't need all that memory for your ladder program? You can opt to store all the documentation (your comments, tag names, etc.) on-board the CLICK CPU as well. This can be especially useful if you find yourself editing the program with a different programming PC in the future.

Math Made Easy

Math Made Easy

Check out the spreadsheet style math instruction, just enter a formula (with embedded PLC tags if you wish) and enter a "result tag". Supports all the standard scientific calculator functions. Make it a "one shot" with a simple check box. It really couldn't be any easier.

Programming Flexibility

NO Limits on Subroutines...

The ladder program can be organized into subroutines with no limit on the number of subroutines other than the total available memory.

...PLUS 8 Interrupt Routines

...PLUS 8 Interrupt Routines

Up to 8 Interrupt routines can also be defined, and can be initiated based on time interval (software interrupt) or via the discrete inputs on the CPU module (external interrupt). Interrupt routines execute immediately, causing the normal PLC scan to be paused. These are great for time-critical operations, especially if the normal scan time of the PLC is high.

Built-in Communications

CLICK CPUs have two or three built-in communications ports. Ethernet ports (when present) are multipurpose, 8 pin RJ45 ports. RS-232 ports are 6-pin RJ12 phone type jacks. Port 3 (when present) is a three wire terminal-block style RS-485 port.

- Port 1 (non-Ethernet models) supports the Modbus RTU protocol only and with fixed communication parameters it is used primarily as the ladder logic programming port. Port 1 can also be used to connect the CPU as a MODBUS RTU protocol slave device.

- Port 1 (Ethernet models) is a full-duplex 10/100 Ethernet port that can be used for programming MODBUS TCP Client/Server and EtherNet/IP Adapter Server communications. (Ethernet port available on all C0-xxxE-x CPU Models)

- Port 2 is a general purpose RS-232 port with user configurable communication parameters. Port 2 can be used as a MODBUS RTU master or slave protocol device, or handle ASCII data ‘In’ or ‘Out’.

- Port 3 (Standard, Ethernet Standard, Analog, Ethernet Analog models only) is a general purpose port with user configurable communication parameters. Port 3 can be used as a MODBUS RTU master or slave protocol device, or handle ASCII data ‘In’ or ‘Out’.

Ports 1 & 2 (serial only) supply 5 VDC, so you can connect our C-more Micro HMI panel without an additional power supply.

Built-in Communications

CLICK 'Standard' CPU Shown

Easy Installation

Easy Installation

The CLICK PLC system does not require a mounting base or rack, which saves money and space. CLICK uses only as much space as needed for a specific application

The CLICK CPU and I/O modules are connected together via an integrated expansion port on the sides of the modules and sliding locking tabs on the top and bottom of all modules.

- Remove the protective cover

- CLICK the neighboring modules together

- Slide the locking tabs to secure

CLICK mounts on standard 35mm DIN rail, or via slide-out mounting feet.

Expandable up to 142 discrete I/O

A basic CLICK CPU module is a complete PLC system by itself, most have eight input points and six output points built-in, or the system can be expanded with the addition of up to eight I/O modules. A variety of I/O modules are available for flexible and optimal system configuration.

View more information about

CLICK I/O modules:

DC I/O modules

AC and Relay I/O modules

Analog I/O modules

Expandable up to 142 discrete I/O

Cut your PLC wiring time down to minutes instead of hours

Cut your PLC wiring time down to minutes instead of hours

The ZIPlink wiring system eliminates the normally tedious process of wiring PLC I/O to terminal blocks. Simply plug one end of a ZIPlink pre-wired terminal block cable into your I/O module and the other end into a ZIPlink connector module. It’s that easy. ZIPlink use half the space, at a fraction of the total cost of terminal blocks.

- One ZIPlink model works with all CLICK modules

- Two ZIPlink Cable styles...

- And three Cable lengths available

Learn more about the CLICK ZIPlink options here.

The CLICK PLC and C-more Micro HMI were made for each other - literally!

- They have the same DNA! The CLICK programming software is based on the popular C-more Micro programming interface - and both are free downloads.

- Both are an excellent value (CLICK starts at: $104.00- C-more Micro starts at: $184.00)

- Use a single cable (as shown) for communications AND power between a CLICK PLC and the 3" C-more Micro models

- Use the same USB programming cable to program both devices

The CLICK PLC and C-more Micro HMI were made for each other - literally!

Decimal Memory Addressing

Decimal Memory Addressing

The I/O numbering system is decimal to make it easier to comprehend, assign and count the I/O points and data registers. Many older PLCs use octal numbering schemes which can be confusing, and also lead to common mistakes.

CLICK Physical I/O points are also numbered starting with 1, instead of 0 to make addressing more straightforward.

CLICK automatically assigns MODBUS addresses to all I/O points and memory registers, to make communications faster and easier.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...