Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wiring Solutions

- Retired Products

- Programmable Logic Controllers

- Productivity1000 PLCs

- Productivity2000 PLCs

- Productivity3000 PLCs

- ProductivityCODESYS

- LS Electric XGB Series PLCs

- ProductivityOpen

- CLICK PLCs

-

Do-more H2 PLCs or

Do-more T1H Series - Do-more BRX PLCs

- C-more Touch Panels

- AC & DC Drives

- Motion Control Components

- Servos

- StrideLinx

- Pneumatics

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

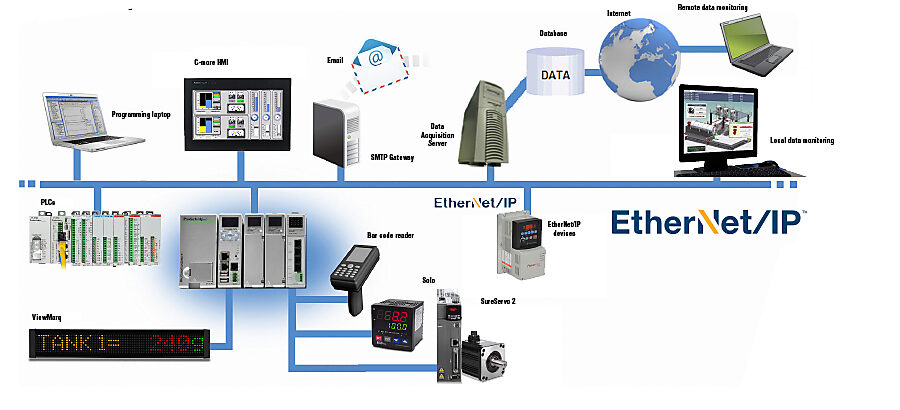

Watch a Video on EtherNet I/P

Scanner/Adapter as a Standard Protocol

Productivity Suite makes communicating with EtherNet/IP devices a snap.

- Scanner and adapter supported

- Implicit application types supported include input-only and listen-only

- EDS file configuration presented in an easy-to-use drop-down menu

- Ability to select multiple connection options from an EDS file which simplifies configuration

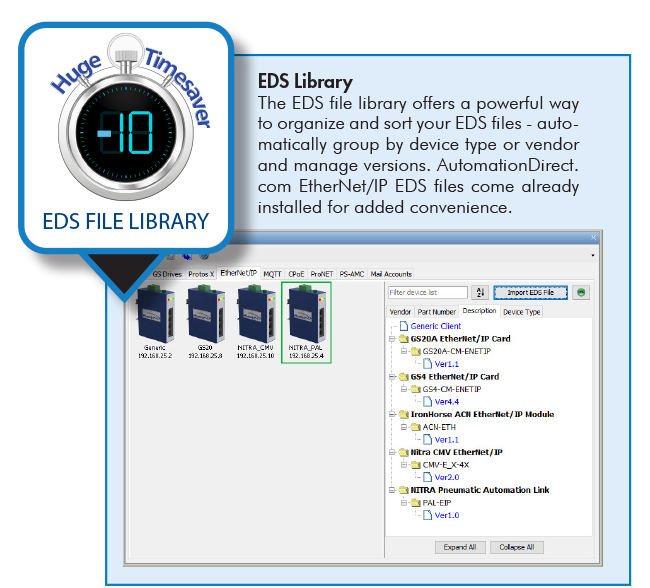

- The EDS file library offers an easy way to upload, store, and manage your EDS files

- AutomationDirect.com EtherNet/IP EDS files are preloaded in the library for convenience

P3000 CPU and I/O Expansion

P3-622

$550.00

CPU with up to 50Mb memory, (2) Ethernet 10/100Base-T (RJ45), (1) RS-232/RS-485 (RJ12), (1) RS-232/RS-485, (1) USB A expansion, (1) USB B port

Base Power Supplies

P3000 Bases and Expansions

3, 5, 8, and 11-slot, local, expansion, and remote I/O bases

AC I/O & Relay Outputs

Analog I/O

DC I/O

Communications and Networking

Motion & Specialty Modules

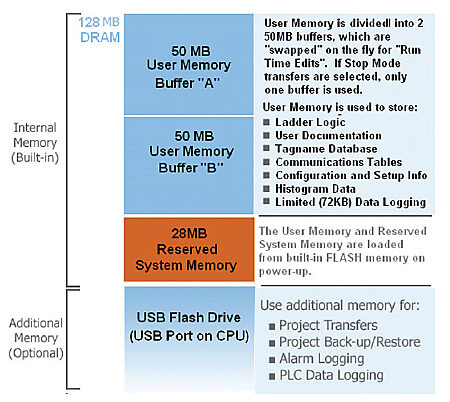

Generous 50 MB of memory

Plenty of storage for your program AND...

Documentation stored on-board

Store your entire project with ALL documentation in the CPU, and never hunt for that old laptop again. You know, the only one that has the updated code from last year when you made all those changes. Sure, we recommend that you keep a backup of all your code and documentation, but who hasn't been burned by this classic PLC problem?

Place any module in any slot

You can install any I/O module in any I/O slot of any base in a Productivity3000 system with no restrictions. The only fixed positions are shown in the figure below; a power supply must be in the power supply slot, and one of the three controllers must go in the CPU slot. Other than this, there are no special slots or rules governing placement of your discrete, analog, or specialty I/O modules.

No power budgeting required!

Both the AC and the DC power supply are powerful enough to power any combination of I/O modules in any size base.

Hot swap I/O modules

Save time and avoid long start-up operations or other down-time related inconveniences. All Productivity3000 I/O modules support hot-swap.

Electronic keying

Once you have determined the desired placement of the I/O modules in your Productivity3000 system, you can enable electronic keying to prevent inadvertent rearrangement or improper replacement of any I/O module.

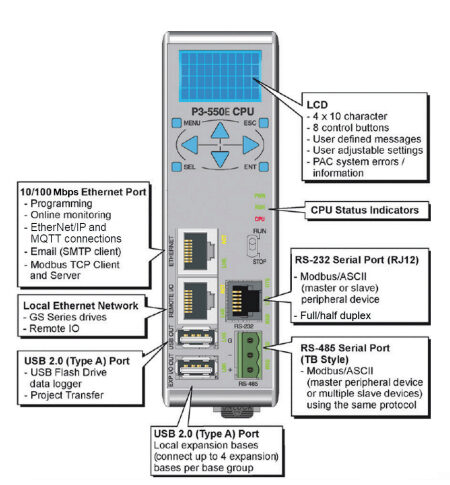

Incredible communications capabilities built in to the CPU

ASCII communications

Use ASCII communications instructions to send and receive non-sequenced String data via a serial port. ASCII communications are typically used for receiving bar code strings from a scanner or sending statistical data to a terminal or serial printer.

Write your own protocol if needed

Send and receive non-sequenced byte arrays with the custom protocol capability. This function is typically used for communicating with devices that don't support the Modbus protocol but do support some other serial protocol.

Seven ports on the P3-622 CPU

The P3-622 CPU has seven ports available to handle a variety of communication needs. You shouldn't have to pay extra or take up valuable slots for each communication port required to solve your application. From Ethernet remote I/O to database connectivity, the Productivity3000 is designed to meet your communication needs.

Two Ethernet ports

The P3-622 CPU has two built-in Ethernet ports. Both can be used as multipurpose Ethernet ports to connect the CPU to HMIs, other controllers, EtherNet/IP devices, cloud computing platforms using MQTT(S), and to your factory network. The secondary Ethernet port also connects to remote slave I/O racks (up to 16), Protos X field I/O racks (up to 4), up to 4 PS-AMC motion controllers and up to 32 variable frequency drives.

CPU programming and monitoring including:

- Real-time data view

- Error history monitoring

- Task management

- Security account management

- CPU configuration

- Ladder logic editing

Ethernet capabilities include:

- Database/enterprise connectivity

- Connect to EtherNet/IP devices

- Connect to cloud networks with MQTT

- Sending e-mail

- Connecting to other factory devices

Two serial ports

The P3-622 CPU has two serial ports built in:

- One RS-232 or RS-485 RJ12 port

- One RS-232 or RS-485 4-wire terminal block port

- Add up to 44 additional serial ports with SCM modules

Both ports support:

- Modbus RTU Master connections

- Modbus RTU Slave connections

- ASCII incoming and outgoing communications

- Custom Protocol incoming and outgoing communications

Add up to 44 additional serial ports with SCM modules

We make cloud communication easy

Industrial machines/systems are more connected than ever before, whether internally with upstream IT management systems or externally with remote support personnel, modern-day plant-floor machines/systems need to communicate to a variety of networks. Cloud networking, with its computing and data storage platforms, has also become a viable solution for analyzing and accessing production data from anywhere at anytime. Using powerful cloud platforms such as Microsoft Azure® or IBM Watson® to analyze production-floor data can provide better process efficiency, improved plant-wide resource management and less operational downtime.

But how does data from a simple level switch on a tank get to the cloud? With Productivity PLCs, it easy! Productivity PLCs have the communication capabilities and processing power needed to not only control plant-floor machines but gather valuable data from them, package it, and send it on to higher level analysis systems.

Multiple data gathering options

Productivity PLCs offer many I/O options to choose from for your system data collection. I/O modules, available in analog, discrete, high-speed, relay, and temperature versions, allow you to create the custom I/O configurations your application needs. And with Modbus RTU, Modbus TCP and EtherNet/IP protocol support, Productivity3000 PLCs can easily gather raw data from a variety of VFDs, sensors, switches, encoders, pilot devices, or almost any other control component your system may have.

MQTT

The MQTT protocol has become the frontrunner for many machine-to-machine (M2M) and IIoT/cloud networking applications, due to its lightweight overhead and reduced bandwidth consumption. Productivity PLCs support MQTT (P3-622 CPU also supports the MQTTS protocol) and with fill-in-the-blank MQTT messaging configurations, delivering vital data to advanced cloud computing platforms is easy.

Compatible with MQTT brokers and cloud platforms/services including:

- IBM Watson®

- Mosquitto®

- HiveMQ®

- Thingsboard®

Refining data into something meaningful

The Productivity Suite programming software makes refining raw data into a meaningful metric a cinch. With a multitude of simple-to-use instructions combined with the computing power of a Productivity CPU, Productivity Suite can easily transform a raw process signal, like 4-20mA, into a consumption rate, a production throughput, an energy efficiency score, a rejection percentage, or any other metric that's vital to you.

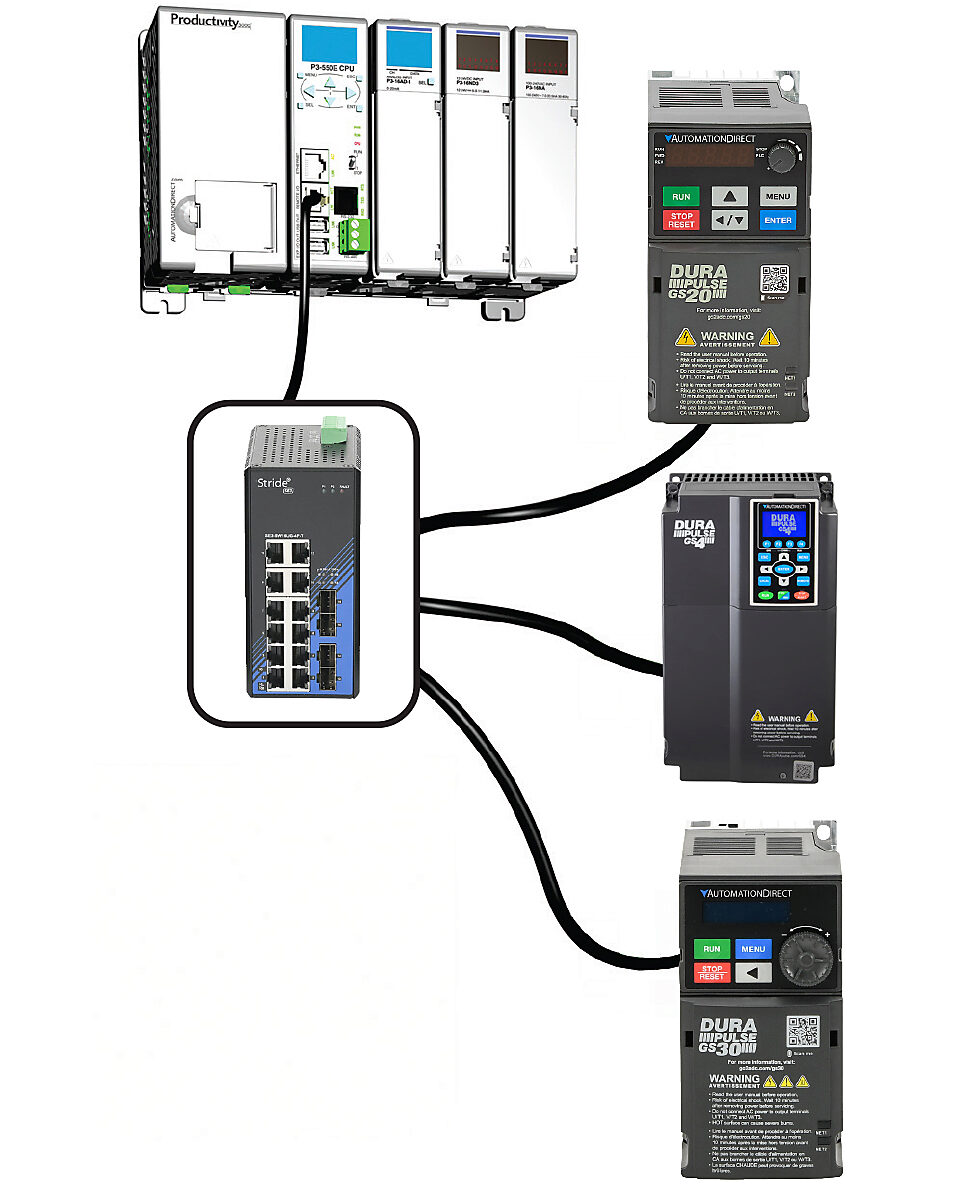

Connect up to 32 VFDs

Connecting your Productivity3000 to variable frequency drives couldn't be easier! Connect up to 32 of our GS series drives via Ethernet, and the Productivity3000 will automatically detect them. The auto-discovery process eliminates the configuration headaches - your drives are ready to program in just a few minutes.

After the auto-discovery process, the dedicated instructions "GS Drives Read" and "GS Drives Write" will prompt the programmer with all the available parameters (in both "run mode" and "stop mode") that can be configured for each model of drive - then it's a cinch to fill in the blanks and program your drives!

Data logging

The Productivity3000 accepts USB-Flash drives and offers this easy-to-configure Data Logger dialog box shown at left. USB drives can be used to log system errors or any type of controller data. Log up to 64 tag values for up to 32GB of data storage. Capture data periodically or when certain events occur.

USB drives can also be used to upload or download a project to/from a Productivity3000 without having a PC present. This feature is great for updating remotely located CPUs - just send your project on a USB drive to any factory in the world, and the controller can be updated with the most current files.

Advanced diagnostics

Patented LCD on all analog modules!

All Productivity3000 analog modules have a four-line LCD on the front panel which provides a quick and easy way to troubleshoot many problems without needing a meter or a PC. Just as you can quickly check the front panel of a discrete module to determine the state of an I/O point, now you can check the status of your analog signals just as easily.

Non-invasive measurements

The LCD allows non-invasive measurements; no need to connect a multimeter in line with the analog signal (which might even affect the signal being measured). View the signal in volts or milliamps (depending on the module) or view the resulting tag value - i.e. 0-65535 (Decimal or Hex) that is being processed by the CPU.

Built-in e-mail capability

If your Productivity3000 is on a network with an SMTP server, it can send e-mails right from your ladder logic. Embed tag data or attach data log files for even more informative messaging. The Send Email instruction makes it simple.

Remote slave connectivity options

The Remote slave module installs in the CPU slot of the first base in each remote base group. It includes two serial communication ports (both supporting Modbus RTU Master/Slave and ASCII In/Out up to 115.2K baud rate): one (1) RS-232 port and one (1) RS-485 port. So each of your remote base groups can connect to additional serial devices.

Affordable ZIPLinks save hours of wiring

We strongly recommend the use of ZIPLink cables and wiring modules, which eliminate the need for hand wiring of I/O modules to DIN rail terminals. In fact, many of the Productivity3000 I/O modules do not include the terminal block for direct connection of I/O. In particular, the high-density (32-point and 64-point) modules require the use of the ZIPLink cables (there simply isn't enough room on the front of these module to terminate that many I/O points).

Don't wait. Get started now for FREE!

The Productivity Suite programming software is available for download free of charge. Take it for a test drive before you buy or get started on your project immediately. There are no licensing fees or maintenance charges to be concerned with and any subsequent upgrades are available for free download as well. If you need assistance, the embedded help file contains detailed information on over 260 topics; also check out our instructional videos or give us a call at 770-844-4200 - we are here to help.

FREE Software!

Download as often as you need. No license or key needed. Click here to download the free software.

Your success is our success!

As the world around us becomes more and more automated, an understanding of electrical control systems becomes more and more vital. To better serve our customers and the industry we rely on, we offer absolutely free online training to anyone looking to learn PLCs. No purchase necessary! This training covers both basic PLC fundamentals as well as specific training on the Productivity Suite Programming Software. Check out this free training here: www.automationdirect.com/plc-training

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...