Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wiring Solutions

- Retired Products

- Programmable Logic Controllers

- Productivity1000 PLCs

- Productivity2000 PLCs

- Productivity3000 PLCs

- ProductivityCODESYS

- LS Electric XGB Series PLCs

- ProductivityOpen

- CLICK PLCs

-

Do-more H2 PLCs or

Do-more T1H Series - Do-more BRX PLCs

- C-more Touch Panels

- AC & DC Drives

- Motion Control Components

- Servos

- StrideLinx

- Pneumatics

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- AC Motors

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

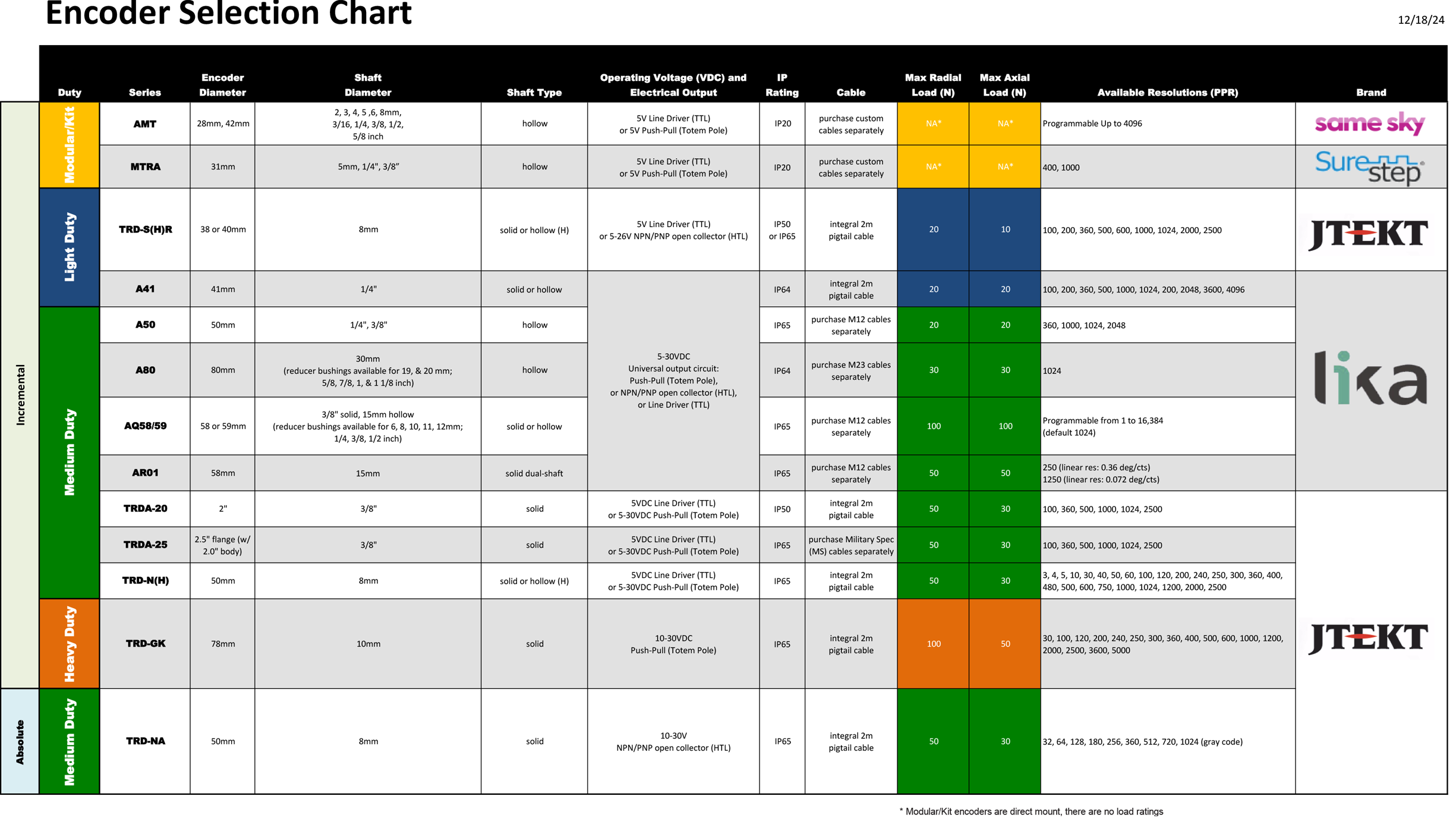

Encoders are used to determine the position, velocity and direction of a motor shaft or other mechanical motion, required for the precise control of applications such as positioning a rotary table, pick and place, packaging, and more. Choose an Incremental or absolute encoder depending on data retention requirements.

This page will refresh momentarily.

Warning

Some of the selected facets have been selected by the {{ assistanceData.title }} Help.

Resetting/clearing ALL facets will end {{ assistanceData.title }} Help.

![Help icon]() Selection Assistance - {{ assistanceData.title }}

Selection Assistance - {{ assistanceData.title }}

Stride Interactive Product Tour Request

Encoders

Category Selection

Incremental Encoders, Absolute Encoders, Measuring Wheel Encoders, Encoder Kits and Accessories

Encoders are used in all types of motion sensing applications, including machine tooling, semiconductor positioning and multi-axis positioning. All encoders feature a reinforced aluminum diecast casing and come equipped with an integral two-meter pigtail cable or connectorized with an MS, M18 or M23 connector. All kit encoders (for stepper motors) are ready-to-mount, with hardware and shaft adapters included.

Use incremental encoders with our PLC high-speed input modules for accurate position monitoring. Absolute encoders (Gray Code output) provide immediate position information on power-up (without a homing sequence) and can be wired to standard PLC DC input cards. Cables, mounting brackets, shaft reducer bushings and flexible couplings are also available.

Availability-Price-Quality

- All our encoders are typically in stock and available for immediate shipment

- As with all our product lines, our prices are often well below the list prices of traditional automation suppliers

- All encoders carry a 1-year warranty and have a 45-day money-back guarantee

For part listings and specifications, go to Shop Now

Rotary Encoders

Newest Additions!

- Lika Electronic rotary and measuring wheel encoders

Rotary encoders utilize a coded target disc and sensing head internal to the encoder to measure rotational motion. The resolution is typically expressed in pulses per revolution (PPR) or lines per revolution (LPR). The pulses produced by these encoders can be used to calculate an object's velocity, distance traveled, position, etc.

Rotary encoders are available in two main types:

- Incremental encoders only provide information about the relative motion of the shaft. They provide no information about shaft location when first powered and only show how far the shaft has moved since the encoder was powered up

- Absolute encoders can detect the initial position of the shaft and know what angle they are at power up.

Several models are available with various output types, speed ratings, diameters, connections, and resolutions (up to 16384 PPR)

Modular Kit Encoders for Step Motors

SureStep® modular encoders for stepper motors and motor/drives are traditional optical encoders with convenient bolt-on options (dual shaft SureStep motors have the proper mounting holes predrilled). Replacement modular encoders for select SureStep® integrated motor/drives are also available.

Extremely rugged AMT series encoders from Same Sky® use state-of-the-art capacitive technology and are available in fixed resolution or configurable models. Configurable models use either DIP switches or the free AMT Viewpoint configuration software to set the resolution (software also allows alignment of the Z-pulse)

- Capacitive or optical encoder technology

- Configurable and fixed resolution models

- Compatible with all dual-shaft stepper motors in various NEMA sizes

- Compatible with select integrated motor/drives

- Quadrature output signals

- Single-ended (totem-pole) and line driver output models

- FREE downloadable configuration software for appropriate models

Encoder Accessories

Simplify your installation with ready-to-use couplings, mounting brackets / flanges, and wiring cables / connectors. Couplings provide a connection between encoders and solid shafts. We offer fiberglass and aluminum couplings for metric, S.A.E. and metric-to-S.A.E. applications. Signal & configuration cables and connectors are also available where optional or required.

- Encoder couplings

- Encoder mounting brackets and flanges

- Servo mount clamps

- Shaft reducer bushings for hollow shaft models

- Replacement encoders and wheels for linear measuring wheel systems

- Programming cables for configurable models

- Encoder cables and connectors

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings