Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

FedEx orders placed before 4:00PM ET on Thursday, April 17th will ship same day. Freight & UPS orders have a 1:00PM ET cutoff. Orders placed after the Thursday cutoff will ship Monday, April 21st.

Note: Due to the Friday holiday, we will not be able to ship next day orders for Saturday or Monday delivery.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wiring Solutions

- Retired Products

- Programmable Logic Controllers

- Productivity1000 PLCs

- Productivity2000 PLCs

- Productivity3000 PLCs

- ProductivityCODESYS

- LS Electric XGB Series PLCs

- ProductivityOpen

- CLICK PLCs

-

Do-more H2 PLCs or

Do-more T1H Series - Do-more BRX PLCs

- C-more Touch Panels

- AC & DC Drives

- Motion Control Components

- Servos

- StrideLinx

- Pneumatics

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- AC Motors

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

The most popular pneumatic actuator style uses compressed air acting on a piston inside a cylinder to move a load. Single-acting cylinders have a single port (air inlet) to extend the piston; an internal spring or sometimes gravity retracts the piston. Double-acting cylinders have separate ports to extend and retract the piston.

This page will refresh momentarily.

Warning

Some of the selected facets have been selected by the {{ assistanceData.title }} Help.

Resetting/clearing ALL facets will end {{ assistanceData.title }} Help.

![Help icon]() Selection Assistance - {{ assistanceData.title }}

Selection Assistance - {{ assistanceData.title }}

Stride Interactive Product Tour Request

Pneumatic Cylinders

Category Selection

There are thousands of industrial applications requiring a linear motion during their operation sequence. One of the simplest and most cost effective ways to accomplish this is with a pneumatic cylinder. Rodded cylinders consist of a piston and rod moving on a linear path inside a closed cylinder when air is applied. This actuator style can be sub-divided into two types based on the operating principle: single acting and double acting.

- Single acting cylinders have a single port to allow compressed air to enter the cylinder to move the piston to the desired position, with a spring or gravity providing the return motion when air is removed.

- Double acting cylinders have a port at each end and move the piston forward and back by alternating the port that receives the high-pressure air.

Pneumatic cylinders are very clean operating devices because the operating fluid is a gas, which prevents drippings from leakage that could contaminate the surroundings. A wide range of body styles, stroke lengths, and bore sizes are available to choose from, with accessories that include position switches and mounting brackets.

For part listings and specifications, go to Shop Now

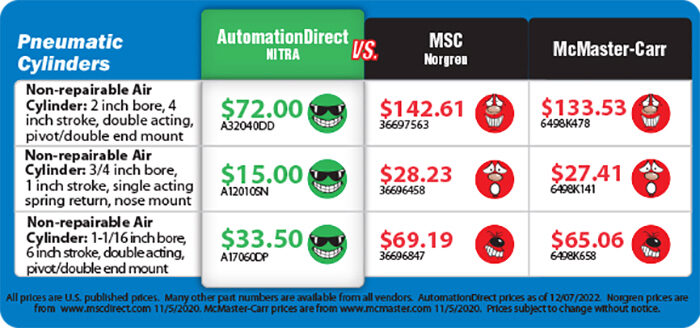

Non-repairable Air Cylinders

Non-repairable cylinders, also known as throw-away cylinders, are designed so that no repairs can be made if/when they no longer function properly; however, replacing these parts is simple and typically costs less in the long run.

- Single-acting and double-acting air cylinders

- Bore sizes up to 2 inches; stroke lengths up to 18 inches

- 3 cylinder mounting configurations

- Type 304 stainless steel round cylinder body with high-strength aluminum alloy end caps

Compact Air Cylinders

Compact stainless steel round body cylinders meet a broad range of applications where space is a concern. These small cylinders are also sometimes referred to as mini cylinders, mini actuators, flat cylinders or pancake cylinders.

- Double-acting mini air cylinders

- Bore sizes up to 3 inches; stroke lengths up to 4 inches

- Interchangeable with other pneumatic mini cylinder brands (pancake cylinders)

- Type 304 stainless steel cylinder body with high-strength aluminum alloy end caps

- Made in the USA

NFPA Tie Rod Air Cylinders

NFPA tie-rod cylinders are held together by four or more threaded tie bolts that run the length of the cylinder and meet the standards established by the National Fire Protection Association. These cylinders are ideal for applications where abusive conditions are a concern.

- Double-acting cylinders

- Bore sizes up to 4 inches; stroke lengths up to 32 inches

- Interchangeable with other common brands of heavy duty cylinders

- Solid high alloy aluminum pistons fitted with magnet and PTFE wear band

- High tensile strength chrome-plated steel piston rods

- High tensile steel torqued tie rods, to allow flexure

- Made in the USA

Dual Guide Rod Air Cylinders

Guided pneumatic cylinders include two adjacent rods to aid in operation stability and position accuracy. The two guide rods and piston are attached to a yoke plate, which prevents the piston from rotating when transverse loads are applied.

- Double-acting cylinders

- Bore sizes up to 63mm; stroke lengths up to 250mm

- Interchangeable with other common brands of guided rod cylinders

- Non-rotate tolerance of +/-0.10° or less

All Stainless Steel Air Cylinders

These non-repairable cylinders feature all stainless steel components to ensure a long cylinder life.

- Double-acting air cylinders

- All stainless steel body, end caps, and rod

- Bore sizes up to 2 inches; stroke lengths up to 18 inches

- 3 cylinder mounting configurations

- Interchangeable with other common brands of round body cylinders

- Made in the USA

ISO 15552 Air Cylinders

ISO 15552 cylinders are very similar in design to NFPA cylinders (US version). They have dimensions that conform to the ISO 15552 standard and include magnetic material on the piston for sensing position.

- Double-acting cylinders

- Fully metric designed to the ISO 15552 standard

- Bore sizes up to 100 mm; stroke lengths up to 600mm

- Flange, pivot and clevis cylinder mount options available

- Adjustable cushions at both ends

Compact Metric Extruded Air Cylinders

Space-saving, compact air cylinders in metric sizes meet a broad range of limited space applications. These high quality cylinders are constructed with hard anodized extruded aluminum bodies and end caps.

- Double-acting compact air cylinders

- Bore sizes up to 100mm; stroke lengths up to 100mm

- Cylinder switch mounting slots are built in to the bodies

- All sizes include a magnet in the piston and a chrome plated steel piston rod

- Nitrite/Buna-N "O" ring rod and piston seals

- Cylinders are factory lubricated for optimum performance and long, reliable life

Air Cylinder Accessories

Accessories for air cylinders include mounting hardware and brackets such as clevis joints, mounting brackets, rod end connectors and locking nuts.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings