Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wiring Solutions

- Retired Products

- Programmable Logic Controllers

- Productivity1000 PLCs

- Productivity2000 PLCs

- Productivity3000 PLCs

- ProductivityCODESYS

- LS Electric XGB Series PLCs

- ProductivityOpen

- CLICK PLCs

-

Do-more H2 PLCs or

Do-more T1H Series - Do-more BRX PLCs

- C-more Touch Panels

- AC & DC Drives

- Motion Control Components

- Servos

- StrideLinx

- Pneumatics

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

Relays have formed the traditional building blocks of control since the 1950s and are still widely used for control or power conversion. Styles range from electro-mechanical or sold state relays to models rated for high power, hazardous locations, and monitoring, alternating, or timing functions.

This page will refresh momentarily.

Warning

Some of the selected facets have been selected by the {{ assistanceData.title }} Help.

Resetting/clearing ALL facets will end {{ assistanceData.title }} Help.

![Help icon]() Selection Assistance - {{ assistanceData.title }}

Selection Assistance - {{ assistanceData.title }}

Stride Interactive Product Tour Request

Relay Switches & Timer Relays

Category Selection

- Electro-Mechanical Relays

- Optocoupler Relays

- Solid State Relays (SSR)

- Phase Monitoring Relays

- Voltage Monitoring Relays

- Alternating Relays

- Pump Seal Failure Relays

- Intrinsically Safe Relays

- Timer Relays

- Multi-Function Digital Counters, Timers and Tachometers

- Relay and Timer Sockets

- Relay and Timer Accessories

Relays and timers provide basic control at a very affordable price and have been a viable automation method for decades. Our general purpose industrial relays are a low-cost way of adding simple control and isolation to any application.

- Electromechanical relays use moving parts to close/open control circuits and are available in cube, open, and card styles for a diverse range of installation requirements

- Optocouplers or optoisolators are used to physically separate circuits from one another but allow electrical signals to be transmitted between them using a light sensitive interface

- Solid state relays don't rely on moving parts that can wear down over time and instead use semiconductor devices like photo-transistors to open or close a circuit

- Specialty relays including phase monitoring, pump seal failure, and alternating relays are designed to perform specific functions that a basic relay can not

- Standard timer relays and digital multifunction timer relays provide reliable timing for automated systems with several timing modes to choose from

Electro-Mechanical Relays

Electro-mechanical relays receive an electrical input that magnetizes an internal coil, causing the relay's contacts to open or close. These relays serve a wide range of industrial applications and are available in a variety of styles to fit specific applications.

- Slim interface relays

- Force guided relays

- General-purpose ice cube relays, plug-in style

- General-purpose octal relays, plug-in style

- Power relays, open style

- Hazardous location (HAZLOC) plug-in relays

- Slim/card relays

Optocoupler Relays

Optocoupler relays provide electrical isolation between the control signal and the load.

- Compact DIN rail mounting

- Load voltages up to 250 VAC/48 VDC

- Current ratings up to 10A

- Model(s) with integrated LED display

- MOSFET, transistor, or TRIAC output options

Solid State Relays (SSR)

Solid state relays use electronic components for switching a load, have no moving parts, and are ideal for applications requiring many/frequent contact closures. Models include general-purpose relays in panel or DIN rail mounting styles.

Phase Monitoring Relays

Newest Additions!

- Dold VARIMETER series phase monitoring relays

Phase monitoring relays protect against equipment failure caused by faults in a 3-phase system, such as phase reversal, phase loss, phase unbalance, overvoltage, and undervoltage (select models also provide fault monitoring for single-phase applications).

- Compatible with Wye or Delta systems

- Range of voltage inputs

- Provide protection even when regenerative voltages are present

Voltage Monitoring Relays

Newest Additions!

- Dold VARIMETER series voltage monitoring relays

Voltage monitoring relays protect equipment from damage caused by faults in a DC or 1-phase AC system, such as overvoltage, undervoltage, or exceeding a voltage band.

These relays are available in a selection of voltage inputs; certain models offer fixed or adjustable drop-out protection.

Alternating Relays

Alternating relays provide significant cost savings and vastly increase equipment life by equalizing the run time of two loads in redundant or lead/lag applications such as pumps, compressors, air conditioning, or refrigeration systems.

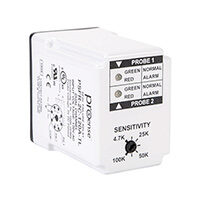

Pump Seal Failure Relays

The most common premature motor failures are caused by bearing issues due to lubrication loss and contamination ingress.

Pump seal failure relays save money by providing an alarm output when a leak is detected, alerting service personnel that routine maintenance is required to protect the motor from irreversible damage.

Intrinsically Safe Relays

Intrinsically safe relays provide a safe and reliable method to control up to four loads (motor starters, relays, etc.) with up to four input devices (switches, sensors, etc.) located in a hazardous area.

All models offer finger-safe design, LED status indicators, and DIN rail or panel mounting options.

Timer Relays

Timer relays provide simple, cost-effective control of processes and machine tools.

- Up to 30A contact ratings

- Cyclic, multi-mode, flasher, off-delay, on-delay, fleeting, and/or on-interval operating modes

- Socket, DIN rail, surface, and panel mounting options

- Easy setup, in settings up to 10,000 hours

Multi-Function Digital Counters, Timers and Tachometers

Versatile digital multi-function relay units are easily configured as a digital counter, timer, combination timer-counter, or tachometer. The two-color LCD shows values, settings, and setup parameters, easily set using the externally accessible DIP switches and the lockable keypad.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...