Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wiring Solutions

- Retired Products

- Programmable Logic Controllers

- Productivity1000 PLCs

- Productivity2000 PLCs

- Productivity3000 PLCs

- ProductivityCODESYS

- LS Electric XGB Series PLCs

- ProductivityOpen

- CLICK PLCs

-

Do-more H2 PLCs or

Do-more T1H Series - Do-more BRX PLCs

- C-more Touch Panels

- AC & DC Drives

- Motion Control Components

- Servos

- StrideLinx

- Pneumatics

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

Crimp contacts for multi-wire connectors slide over a stripped wire and must be carefully matched to the correct size wire to achieve secure termination. Crimp contacts, made of hard silver-plated or gold-plated copper alloy, are available in various sizes and amperage ratings.

This page will refresh momentarily.

Warning

Some of the selected facets have been selected by the {{ assistanceData.title }} Help.

Resetting/clearing ALL facets will end {{ assistanceData.title }} Help.

![Help icon]() Selection Assistance - {{ assistanceData.title }}

Selection Assistance - {{ assistanceData.title }}

Stride Interactive Product Tour Request

Multi-Wire Connectors

Inserts

Newest Additions!

- METEcon multi-wire connector inserts

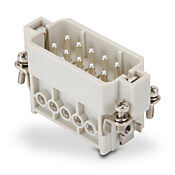

Inserts provide the wiring connections and are mounted between the hood and the base of the multi-wire connector assembly or a one-piece housing.

- Available in screw terminal or crimp style contact block connections

- Self-extinguishing thermoplastic reinforced with glass fibers

- Asymmetric guide rails prevent incorrect coupling

- Captive installation screws allow for easy and secure installation

- Laser-printed or molded terminal/contact positions on both sides of insert

- Wide contact surface for ground terminals

- IP20 without enclosures

- Suitable for stranded and solid conductors

Housings

Newest Additions!

- METEcon multi-wire connector housings

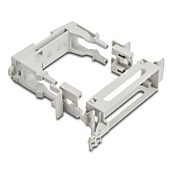

Housings are available in hoods, bases, couplers, and bulkhead and surface mount configurations which provide a protective covering for the insert and wiring.

All housings are available in a standard profile. Several are offered with a high construction (HC) profile that allows more room for wiring the higher-density inserts.

- Available with top entry or side entry cable passages

- Straight or angled models

- Thermoplastic or aluminum construction

- Various dimensions and sizes

- PG and NPT thread options available for conduit connection

- IP68 or IP66 cable glands for cable entry offered with select models

Crimp Contacts

Newest Additions!

- METEcon multi-wire connector crimp contacts

For use with crimp style inserts, crimp contacts are securely connected to bare wires and installed into the multi-wire insert. A perfect crimp connection is gas-tight, corrosion free, and is equal to a cold weld of the parts being connected.

- Made of silver-plated or gold-plated copper alloy

- Female or male contacts, sold in 100-packs

- 10 Amp, 26-14 AWG and 16 Amp, 26-12 AWG sizes

- Use crimp contact tool for proper crimping

Plugs, Adapters, and Cable Glands

Plugs, adapters, and cable glands provide IP protection and support for cable connections to housings or bases.

- IP66 protection with plastic or metal cable glands

- IP68 protection with metal cable glands

- Adapters convert a PG thread to an NPT thread

- Blanking plugs with gaskets to seal unused ports

Housing Insert Plates

Housing insert plates provide a way to secure non-standard connectors, including 9-pin D-sub connectors, into a housing component.

- Single and dual 9- and 15-pin D-sub connector cutouts

- Blank cover plates or plates with selections

- Bulkhead cutout reducing insert plates selections available

- Thermoplastic construction with gasket included

Code Pins and Polarization Keys

Code pins are used in applications where there are identical connectors that could be coupled with the incorrect mate, potentially causing equipment damage or breakdown. Code pins replace the installation screws on the inserts.

Polarization keys provide a safe way for connectors to align properly, ensuring proper polarity.

Code Pins

- Single code pin or double code pin with male and female versions

- Sold in quantity packs

- Zinc-plated steel construction

Polarization Keys

- Fits 3A 12-pin inserts

- Two keys are required per coupled connection

- 12 red keys per pack

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...